October 2024

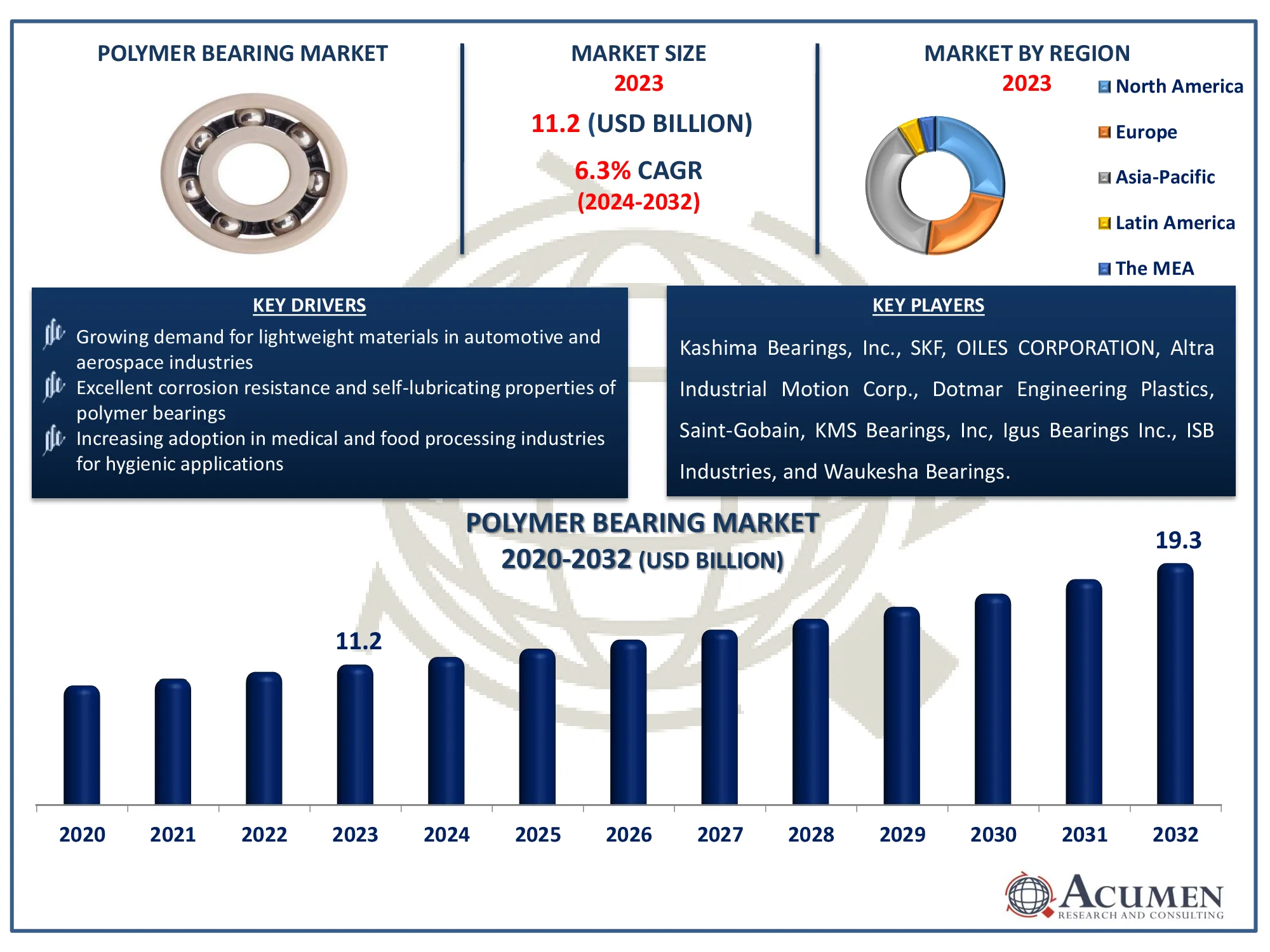

The Global Polymer Bearing Market Size accounted for USD 11.2 Billion in 2023 and is estimated to achieve a market size of USD 19.3 Billion by 2032 growing at a CAGR of 6.3% from 2024 to 2032.

The Global Polymer Bearing Market Size accounted for USD 11.2 Billion in 2023 and is estimated to achieve a market size of USD 19.3 Billion by 2032 growing at a CAGR of 6.3% from 2024 to 2032.

Polymer bearings are often used in settings that require resistance to moisture or chemicals. They provide a variety of benefits, including corrosion resistance, high wear and fatigue resistance, self-lubrication, low friction, quiet operation, lightweight, high strength, great dimensional stability, lower lifespan costs, and electrical insulation. These bearings are used extensively in a variety of industries, including food and beverage, medical, textile, chemical, photographic, and vacuum systems.

|

Market |

Polymer Bearing Market |

|

Polymer Bearing Market Size 2023 |

USD 11.2 Billion |

|

Polymer Bearing Market Forecast 2032 |

USD 19.3 Billion |

|

Polymer Bearing Market CAGR During 2024 - 2032 |

6.3% |

|

Polymer Bearing Market Analysis Period |

2020 - 2032 |

|

Polymer Bearing Market Base Year |

2023 |

|

Polymer Bearing Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Type of Bearing, By Material, By Application, By End-Use Industry, and By Geography |

|

Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Kashima Bearings, Inc., SKF, OILES CORPORATION, Altra Industrial Motion Corp., Dotmar Engineering Plastics, Saint-Gobain, KMS Bearings, Inc, Igus Bearings Inc., ISB Industries, and Waukesha Bearings. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

The polymer bearing market is quickly developing, propelled by rising demand in Asia-Pacific's emerging economies, including India, China, Brazil, Argentina, and the UAE. Their growing use in industries such as semiconductors, medical and pharmaceuticals, chemicals, autos, food processing, and textiles fuels market expansion. Polymer bearings are widely utilized on metal surfaces and provide significant advantages over traditional bearing materials. They can tolerate chemicals and corrosion, and as self-lubricating components, they limit heat transfer inside mechanical assemblies, minimizing the chance of failure due to reduced maintenance requirements.

However, strict regulatory regulations on the use of polymer bearings in the packaging and food processing industries stifle industry expansion. Furthermore, the market faces obstacles due to a lack of understanding about the benefits of polymer bearings.

The growing need for lightweight materials in the automotive and aerospace industries is fueling the growth of the polymer bearing market. For example, the Department of Energy says that lightweight materials have significant potential to improve vehicle efficiency. Using lightweight components and high-efficiency engines enabled by new materials in one-quarter of the US fleet could save more than 5 billion gallons of petroleum per year by 2030.

The increased demand for lightweight components in electric vehicles presents an opportunity for the polymer bearing market. According to the International Energy Agency (IEA), electric LCVs increased their market share quicker than passenger light-duty vehicles (PLDVs), albeit from a lower starting position, across the majority of leading EV markets, including the United States, Japan, and Europe. Although electric SUVs accounted for around 35% of all electric passenger light-duty vehicles (PLDVs) in 2022, their share of oil displacement was substantially higher (almost 40%), as SUVs are driven more frequently than smaller autos.

The worldwide market for polymer bearing is split based on type of bearing, material, application, end-use industry, and geography.

According to the polymer bearing industry analysis, ball bearings shows robust growth because they are versatile and widely used in applications that require high precision, low friction, and effective load handling, such as motors, gears, and medical equipment. Roller bearings are typically utilized in applications requiring high load capacities and durability, such as heavy machinery, conveyor systems, and industrial equipment. They provide outstanding performance and reliability.

According to the polymer bearing industry analysis, nylon is a popular material because of its high strength, wear resistance, and low friction qualities. It has outstanding mechanical qualities, making it appropriate for heavy-duty applications while remaining durable over time. Furthermore, nylon's resistance to moisture and chemicals improves its effectiveness in a variety of settings, decreasing the requirement for lubrication. Because of their adaptability, nylon bearings are widely used in automotive, industrial, and other demanding applications that require dependability and cost-effectiveness.

According to the polymer bearing market forecast, motors are expected to experience notable growth as they are widely used in industries such as automotive, aerospace, and electronics. Polymer bearings are essential for improving motor efficiency and durability because to their self-lubrication, corrosion resistance, and lightweight design. Polymer bearings help gears reduce friction and increase longevity, while drive shafts improve performance and durability. Idler wheels and wheel pivots benefit from their low noise and low maintenance features, allowing for more efficient operations. Polymer bearings in X-ray robots are prized for their nonmagnetic, low-friction properties, which are critical in medical applications.

According to the polymer bearing market forecast, automotive segment dominates due to increasing demand for lightweight, robust, and low-maintenance vehicle components. Polymer bearings are widely utilized in applications like steering systems, transmissions, wipers, and seating mechanisms due to their self-lubricating nature and resilience to wear and corrosion. These bearings help to improve fuel efficiency and minimize emissions in vehicle systems by reducing friction and weight. The growing popularity of electric and hybrid vehicles fuels the demand for polymer bearings in the automotive industry.

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

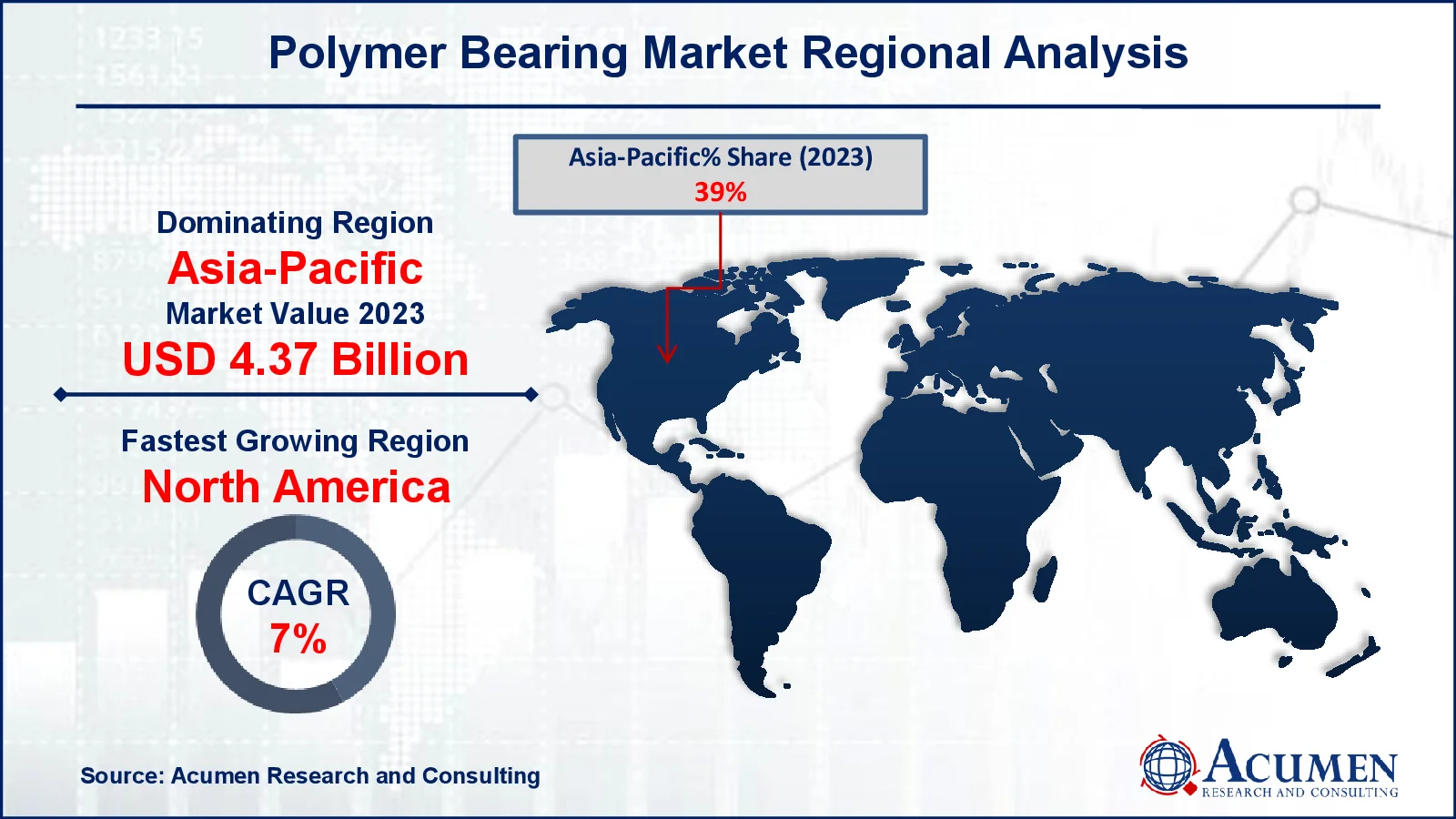

Asia-Pacific region has emerged as the leading market for polymer bearings. Increased foreign firm investments, expanding manufacturing facilities, a strong industrial base in the building industry, and major improvements in living standards are all important drivers of development in this region. For example, China's industrial output will increase in 2023. In 2023, the output of the equipment manufacturing industry climbed by 6.8 percent year on year, above the general growth rate in industrial production. The production of solar batteries, new energy vehicles, and power generation equipment climbed by 54%, 30.3%, and 28.5% respectively. The LAMEA region's growth is primarily driven by rising demand from a variety of end-use sectors.

North America is experiencing rapid growth in the polymer bearing market. Growing industrialization promotes market growth in region. According to the US Department of Defense, "America's manufacturing ecosystem has been a vital engine of economic growth, innovation, and competitiveness for over 200 years, and has played a critical role in developing and driving the technologies that sustain our national security," stated the undersecretary of defense for acquisition and sustainment during an address commemorating Manufacturing Month in October. As an economic growth engine, American manufacturers provide more than $2.35 trillion to the US economy—every dollar spent in manufacturing returns an additional $2.79 to the economy, making it the sector with the greatest multiplier effect.

Leading players in the polymer bearing market are pursuing tactics such as mergers and acquisitions with both domestic and established organizations. They are also aggressively partnering with regional players to broaden their geographic reach and optimize earnings. Partnerships with international firms to expand market reach and brand recognition are also anticipated to be important tactics for success in the polymer bearing market.

Some of the top polymer bearing companies offered in our report includes Kashima Bearings, Inc., SKF, OILES CORPORATION, Altra Industrial Motion Corp., Dotmar Engineering Plastics, Saint-Gobain, KMS Bearings, Inc, Igus Bearings Inc., ISB Industries, and Waukesha Bearings.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

October 2024

April 2023

October 2022

July 2024