April 2025

Explore the expanding Acrylonitrile Butadiene Styrene market from USD 21.2 billion in 2022 to an estimated USD 33.1 billion by 2032 with a 4.8% CAGR. Learn about the driving forces, including demand in lightweight automobiles and applications in electronics and appliances.

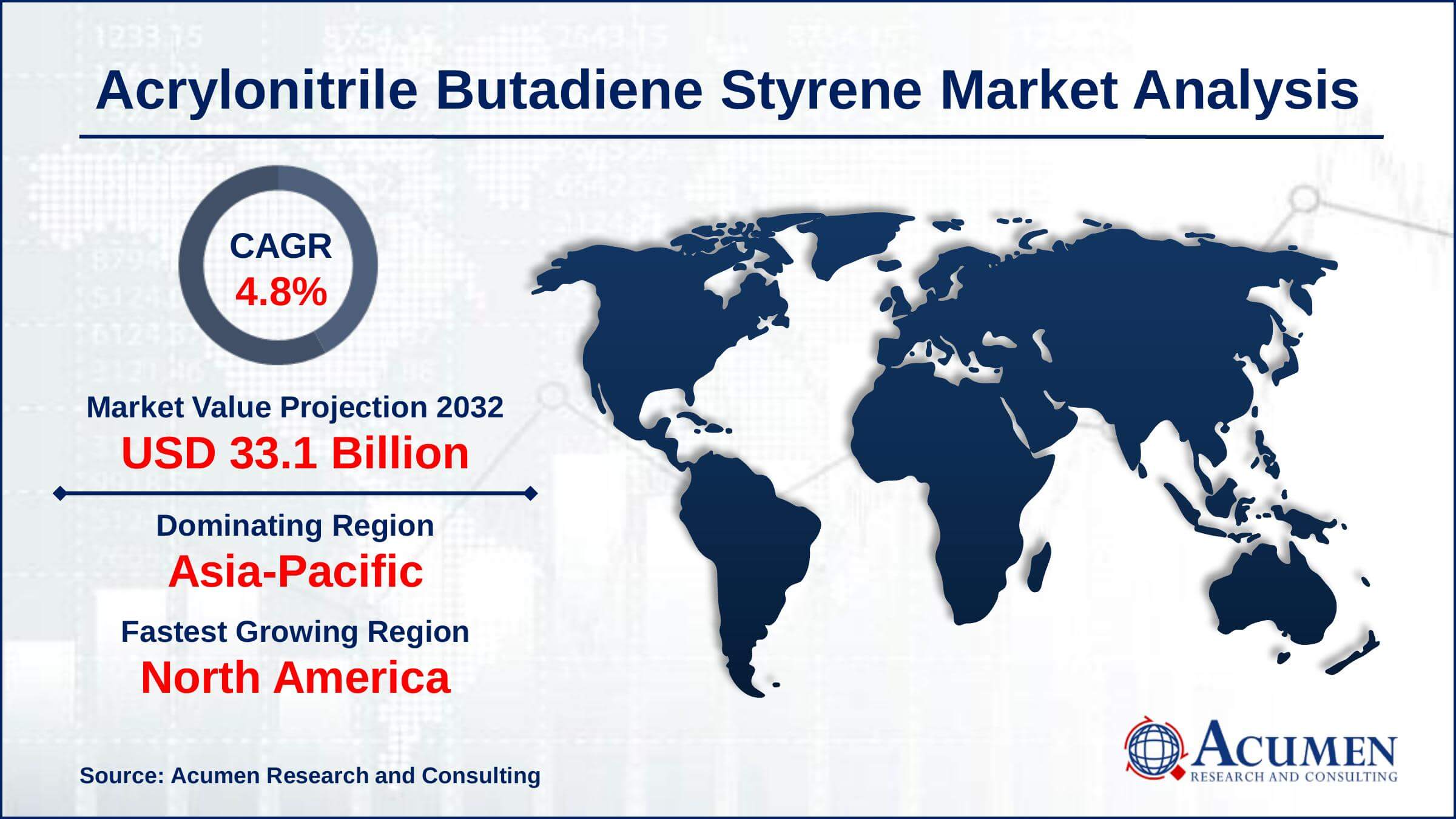

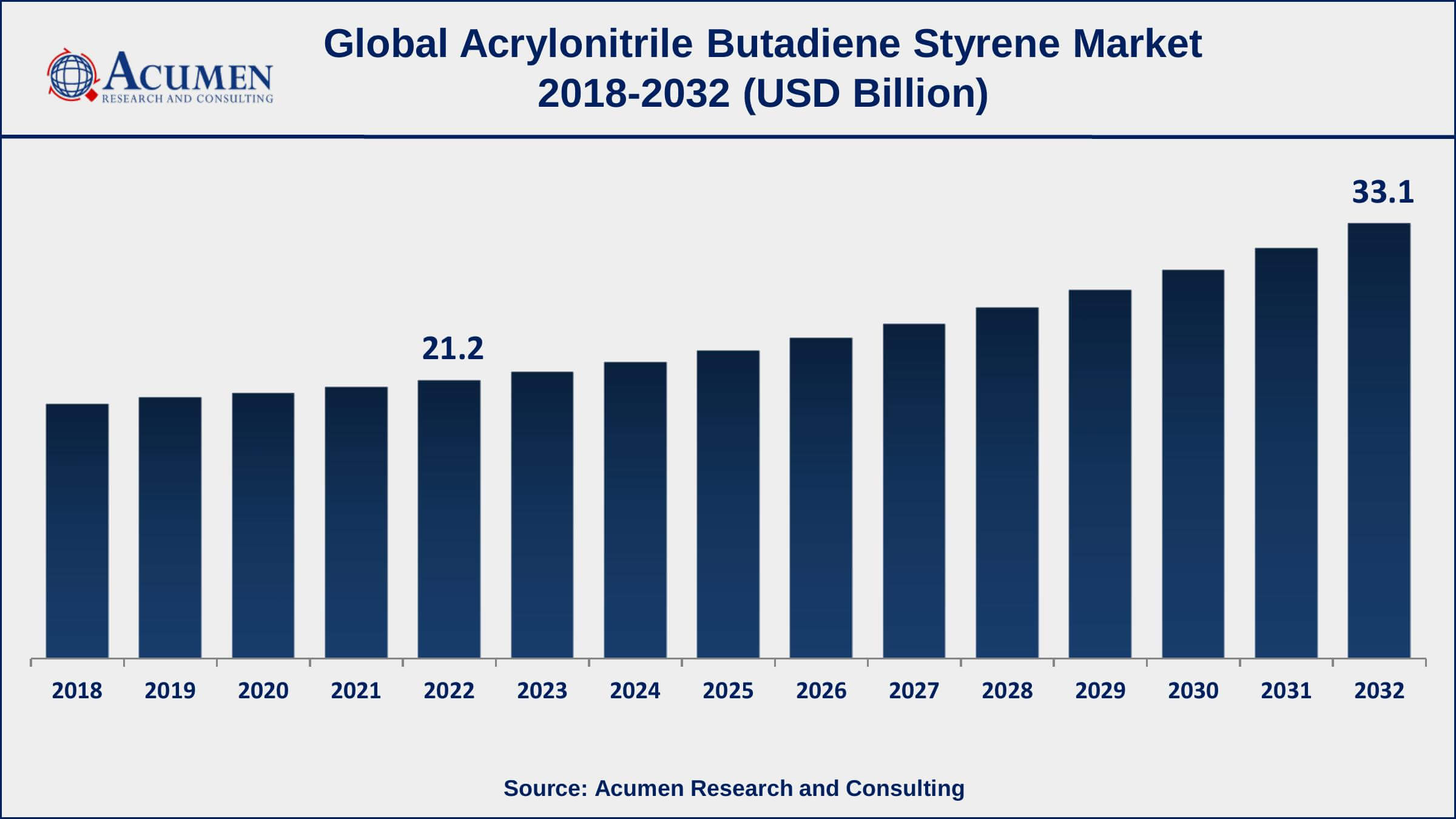

The Global Acrylonitrile Butadiene Styrene Market Size accounted for USD 21.2 Billion in 2022 and is estimated to achieve a market size of USD 33.1 Billion by 2032 growing at a CAGR of 4.8% from 2023 to 2032. The growing demand for lightweight and fuel-efficient automobiles is driving the acrylonitrile butadiene styrene (ABS) market growth. Furthermore, ABS is utilized in the manufacture of electronic goods and appliances, which is predicted to boost the acrylonitrile butadiene styrene (ABS) market value in the coming years.

Acrylonitrile Butadiene Styrene Market Report Highlights

Acrylonitrile butadiene styrene has a chemical formula of (C8H8)x•(C4H6)y•(C3H3N)z and is a popular thermoplastic. The glass transition temperature of acrylonitrile butadiene styrene is around 105°C. Since acrylonitrile butadiene styrene is amorphous. Acrylonitrile butadiene styrene is a terpolymer and is manufactured by the polymerization of acrylonitrile and styrene in the occurrence of polybutadiene. Moreover, the proportions of the aforementioned chemicals may vary from 5% to 30% butadiene, 40% to 60% styrene, and 15% to 35% acrylonitrile. The resulting product is a long chain of crisscrossed polybutadiene with short chains of poly(styrene-co-acrylonitrile). The nitrile groups are polar and thus attract each other to bind the above-mentioned chains, making acrylonitrile butadiene styrene stronger as compared to pure polystyrene. The styrene present in the acrylonitrile butadiene styrene provides an impervious and shiny surface. Polybutadiene is a rubber-like substance that provides toughness at low temperatures.

Acrylonitrile Butadiene Styrene Market Trends

Market Drivers

Market Restraints

Market Opportunities

Acrylonitrile Butadiene Styrene Market Report Coverage

| Market | Acrylonitrile Butadiene Styrene Market |

| Acrylonitrile Butadiene Styrene Market Size 2022 | USD 21.2 Billion |

| Acrylonitrile Butadiene Styrene Market Forecast 2032 | USD 33.1 Billion |

| Acrylonitrile Butadiene Styrene Market CAGR During 2023 - 2032 | 4.8% |

| Acrylonitrile Butadiene Styrene Market Analysis Period | 2018 - 2032 |

| Base Year | 2022 |

| Forecast Data | 2023 - 2032 |

| Segments Covered | By Type, By Application, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | LG Chemicals, BASF SE, Asahi Kasei Corporation, KUMHO PETROCHEMICAL, CHIMEI, SABIC, Formosa Plastics Corporation, INEOS Styrolution Group GmbH, DuPont, and Trinseo. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Acrylonitrile butadiene styrene is a well-known thermoplastic and offers superior properties such as impact and chemical resistance, processing versatility, and superlative balance of heat. It finds applications in a variety of processes in the transportation, construction, electronics, appliances, and pharmaceutical sectors. Rapid growths in the automotive and construction industry as well as rapid industrialization are some factors driving the market growth over the forecast period. Due to the vast number of market players and increased competition, consumers are projected to gain tremendous benefits. Acrylonitrile butadiene styrene can be produced by the process of polymerization including emulsion, mass process, and suspension. Suspension and emulsion are the most preferred methods, however, the mass process has earned a significant role owing to the feasible polymerization along with the ease of handling. The mass process of manufacturing acrylonitrile butadiene styrene involves the polymerization of acrylonitrile and styrene in the presence of styrene butadiene rubber, polybutadiene and nitrile butadiene rubber in the monomer phase.

The growth of the automotive sector coupled with increasing demand for lightweight yet tough plastics in automobiles is a key factor driving the demand for ABS market size. Moreover, the rapid growth of the Chinese chemical industry has fueled the demand for engineering plastics, and in turn, is accelerating the growth of the overall market. The rising importance of lightweight materials to achieve better fuel efficiency is anticipated to fuel the growth of the market. Improvements in Corporate Average Fuel Economy standards have encouraged automobile manufacturers to opt for new materials with lighter weights in order to increase fuel efficiency. This is acting as a key factor in the growth of the ABS market.

Market Segmentation

The global acrylonitrile butadiene styrene market segmentation is based on type, application, and geography.

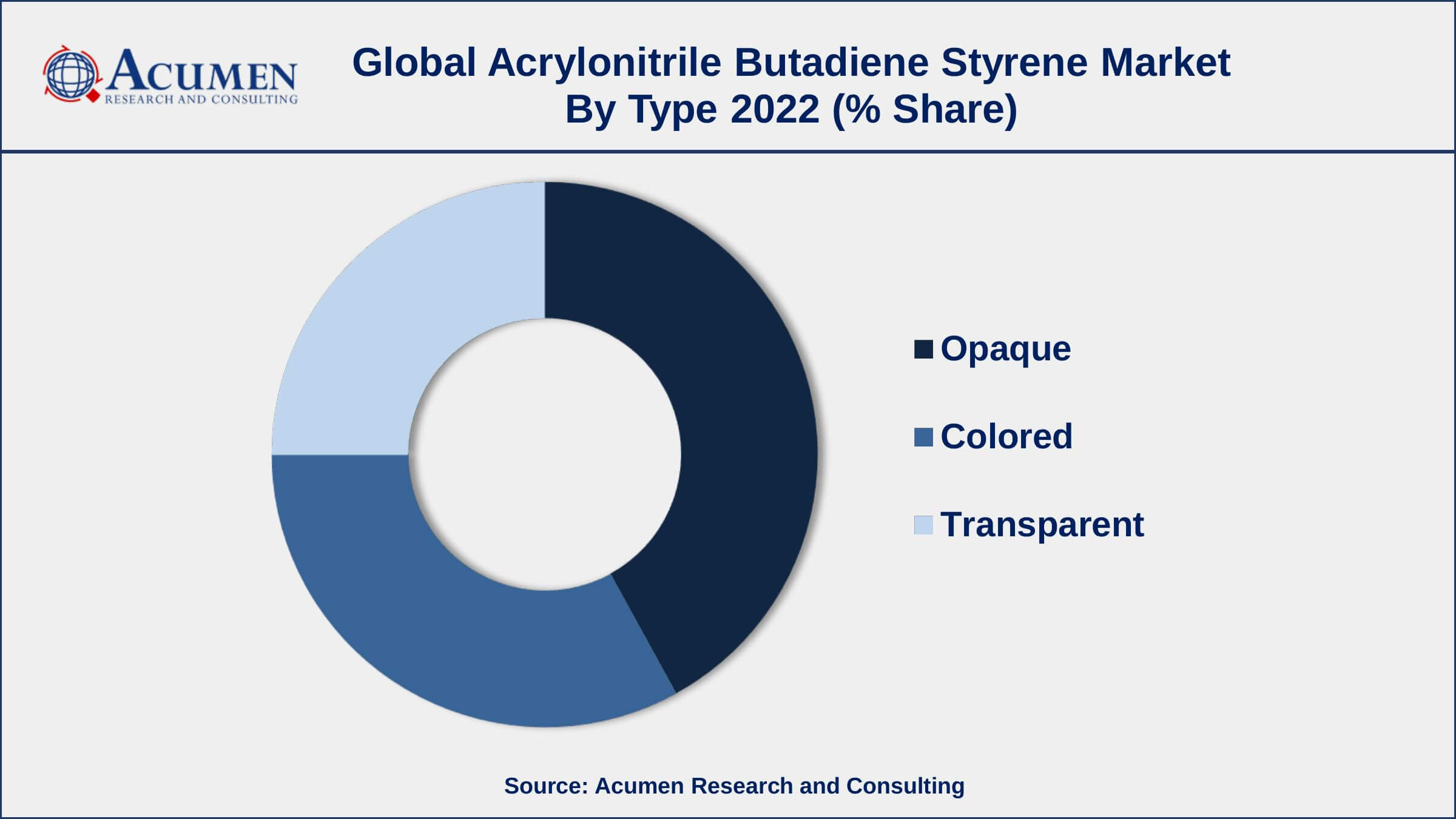

ABS Market By Type

According to the acrylonitrile butadiene styrene industry data, the opaque sector held the greatest market share in 2021. This growth is primarily driven by rising demand for ABS in a variety of end-use industries, including automotive, construction, consumer products, and healthcare. ABS is a thermoplastic polymer that is known for its high-impact strength, good dimensional stability, and excellent surface finish. It is widely used in the production of lightweight and high-performance vehicles, window frames, pipes, electrical appliances, toys, household appliances, and electronic devices.

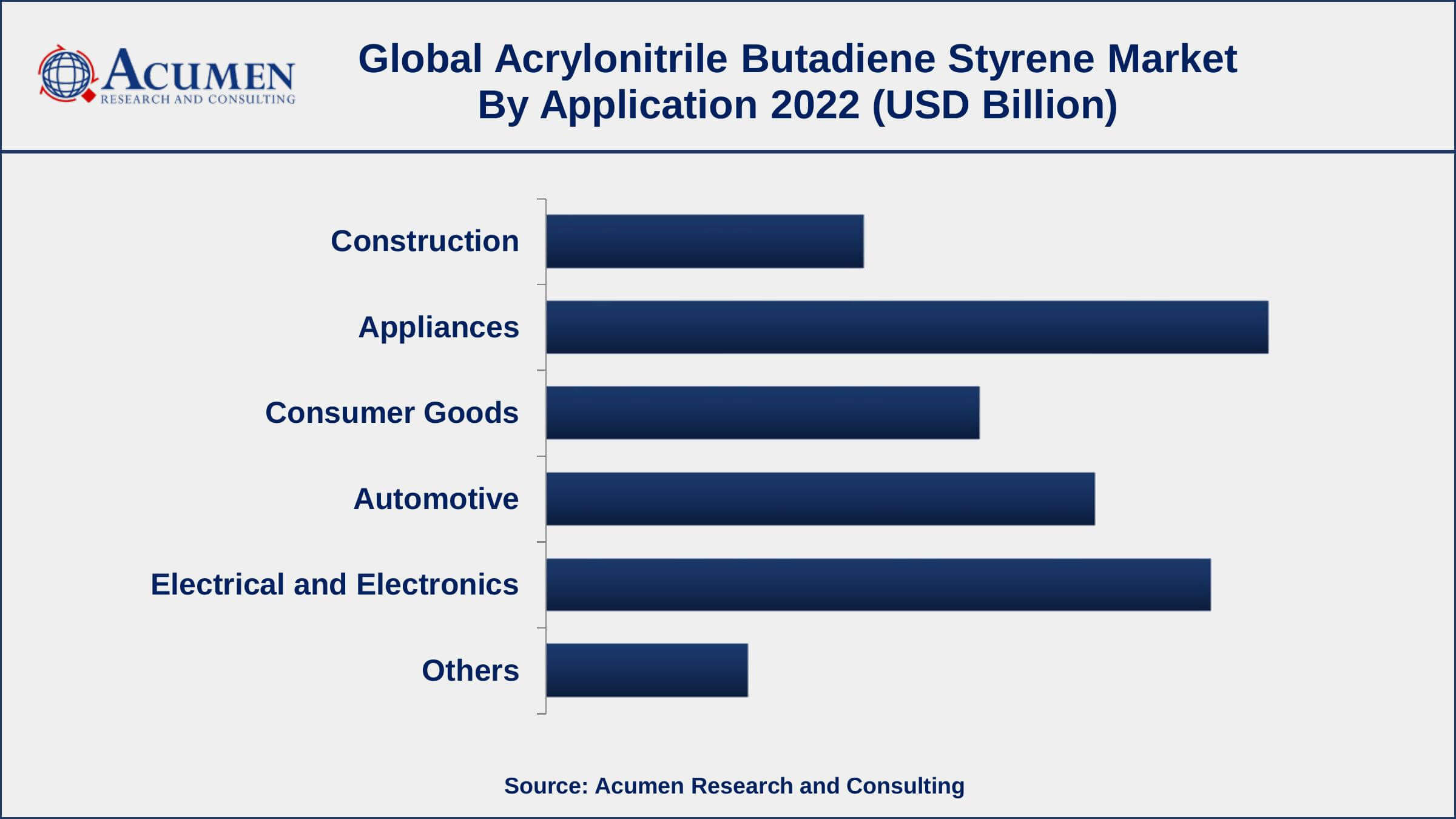

ABS Market By Application

According to the acrylonitrile butadiene styrene market forecast, the appliance segment is projected to grow significantly in the market over the next few years. The increasing demand for ABS in the production of household goods such as refrigerators, washing machines, air conditioners, and microwave ovens is driving this growth. ABS is widely used in the production of appliances due to its high impact strength, good dimensional stability, and excellent surface finish. ABS is used in the production of appliances in various forms such as sheets, pipes, and injection-molded parts. It is commonly used in the production of the outer shells of appliances, as well as internal components such as door handles, knobs, and control panels. ABS is also used in the production of refrigerator liners, washing machine drums, and air conditioner casings.

Acrylonitrile Butadiene Styrene Market Regional Outlook

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Geographically, Asia-Pacific region is currently dominating the acrylonitrile butadiene styrene (ABS) market. This is primarily due to the increasing demand for ABS in various end-use industries, such as automotive, construction, and electronics, in countries such as China, India, and Japan. Additionally, the region's growing population and rising disposable income levels are also contributing to the growth of the ABS market in Asia-Pacific. The region is also witnessing significant investments in the expansion of the production capacities of ABS manufacturers, which is further boosting market growth. Furthermore, the growing adoption of ABS in the construction industry, particularly in China and India, is also projected to drive market growth in the region. The automotive industry is also a major contributor to the growth of the ABS market in Asia-Pacific. The increasing demand for lightweight and fuel-efficient vehicles is leading to the increased use of ABS in the automotive industry in the region.

Acrylonitrile Butadiene Styrene Market Players

Some of the top acrylonitrile butadiene styrene market companies offered in the professional report include LG Chemicals, BASF SE, Asahi Kasei Corporation, KUMHO PETROCHEMICAL, CHIMEI, SABIC, Formosa Plastics Corporation, INEOS Styrolution Group GmbH, DuPont, and Trinseo.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

April 2025

May 2020

June 2022

January 2025