January 2023

Artificial Intelligence in Manufacturing Market Size accounted for USD 3.7 Billion in 2023 and is estimated to achieve a market size of USD 80.3 Billion by 2032 growing at a CAGR of 41.3% from 2024 to 2032.

The Artificial Intelligence in Manufacturing Market Size accounted for USD 3.7 Billion in 2023 and is estimated to achieve a market size of USD 80.3 Billion by 2032 growing at a CAGR of 41.3% from 2024 to 2032.

Artificial Intelligence in Manufacturing Market Highlights

Recent trends in the global artificial intelligence (AI) in manufacturing market include the increasing adoption of 5G technology and the growing use of computer vision in manufacturing applications. Our analysis predicts that the rapid demand for factory automation will drive industry growth throughout the forecast period. Consequently, the industry is expected to register a compound annual growth rate (CAGR) of 41.3% from 2024 to 2032. Many manufacturing operations are leveraging AI to streamline processes and boost productivity. AI helps the industry address various internal challenges, such as lack of expertise, complex decision-making, compatibility issues, and information overload. By integrating AI, manufacturing plants can completely transform their operations, leading to a significant boom in AI adoption within the manufacturing sector.

Global Artificial Intelligence in Manufacturing Market Dynamics

Market Drivers

Market Restraints

Market Opportunities

Artificial Intelligence (AI) in Manufacturing Market Report Coverage

| Market | AI in Manufacturing Market |

| Artificial Intelligence (AI) in Manufacturing Market Size 2022 | USD 3.7 Billion |

| Artificial Intelligence (AI) in Manufacturing Market Forecast 2032 |

USD 80.3 Billion |

| Artificial Intelligence in Manufacturing Market CAGR During 2024 - 2032 | 41.3% |

| Artificial Intelligence in Manufacturing Market Analysis Period | 2020 - 2032 |

| Artificial Intelligence in Manufacturing Market Base Year |

2022 |

| Artificial Intelligence in Manufacturing Market Forecast Data | 2024 - 2032 |

| Segments Covered | By Offering, By Technology, By Industry Vertical, By Industry Vertical, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Amazon Web Services, Bosch, Cisco Systems, Foxconn General Electric Company, Google, Inc., IBM Corporation, Intel, Inc., Microsoft Corporation, Nvidia Corporation, Rockwell Automation, SAP SE, and Siemens AG. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Artificial Intelligence in Manufacturing Market Insights

The growing adoption of IoT and big data in manufacturing industries is the primary factor driving the artificial intelligence in manufacturing market growth. IoT will enable the delivery of supplies and services to the customer who may be unaware that they are required. Furthermore, IoT can send detailed telemetry back to manufacturers and distributors in order to scrutinise quality and factors that may cause failures. Similarly, the adoption of big data will also surge the share of the market in coming future. For instance, manufacturers collect vast amounts of data related to operations, processes, and other matters and this data, combined with advanced analytics, can provide valuable insights to improve the business. Thus, big data can benefit manufacturers with supply chain management, predictions on sales volume, risk management, and product quality maintenance.

The global AI in manufacturing market is getting a big boost from the fast-paced adoption of industrial automation. AI and automation have evolved significantly, thanks to better machine learning, improved sensors, and more powerful computers. This has led to the development of a new breed of robots that are smarter and more efficient than ever before. On top of that, the rise of Industry 4.0 is fueling even more growth in this market. However, there's a hurdle to overcome: the need for advanced infrastructure, which comes with a hefty initial investment. Despite this challenge, the potential for growth and innovation in AI-driven manufacturing is immense.

Artificial Intelligence in Manufacturing Market Segmentation

The worldwide market for AI in manufacturing is split based on component, type, power output, application, and geography.

AI in Manufacturing Offering

According to artificial intelligence in manufacturing industry analysis, the hardware segment is poised to take the lead in the market share over the projected years. This segment encompasses crucial components like processors and logic circuits, essentially powering the AI software. With AI's demand for dedicated processing units, the need for hardware is expected to rise significantly. Moreover, our research suggests that AI hardware vendors are bolstering their market presence through new partnerships, acquisitions, and innovative product developments, further propelling the demand for hardware. On the flip side, while the software segment is projected to witness the fastest growth rate in the coming years, it's the hardware segment that is set to dominate initially.

AI in Manufacturing Technology

In 2023, machine learning emerged as the dominant force in the artificial intelligence in manufacturing market, claiming the highest market share among all technologies. This trend stems from the increasing imperative to ensure stringent quality management across every facet of the manufacturing process. Leveraging AI and machine learning, manufacturers can achieve unprecedented levels of efficiency, optimize supply chain operations, and accelerate research and development endeavors. Moreover, machine learning plays a pivotal role in bolstering preventive maintenance strategies for all equipment on the factory floor. By harnessing predictive analytics and real-time data insights, manufacturing businesses can proactively address potential issues, thereby minimizing downtime and maximizing productivity. This proactive approach not only enhances operational efficiency but also contributes to cost savings and competitive advantage in the industry.

AI in Manufacturing Application

As per our artificial intelligence (AI) in manufacturing market analysis, the applications of predictive maintenance and machinery inspection are of paramount importance in manufacturing facilities. Predictive maintenance allows companies to accurately predict when machines require maintenance, rather than relying on guesswork or performing preventive maintenance based on a fixed schedule. By leveraging machine learning, predictive maintenance helps prevent unplanned downtime, thereby optimizing operational efficiency. Furthermore, advanced analytics and sensors embedded in manufacturing systems enable predictive maintenance by promptly reacting to alerts and resolving machine issues before they escalate. This proactive approach not only minimizes downtime but also enhances productivity and cost-effectiveness in manufacturing operations.

AI in Manufacturing Industry Vertical

Based on the artificial intelligence in manufacturing market analysis, the automotive category has been a significant contributor to the industry revenue throughout the forecasted years of 2024 to 2032. Key factors driving this contribution include the widespread adoption of highly advanced AI automotive solutions for smart manufacturing, fault detection and isolation, production monitoring, quality management, and the increasing demand for predictive maintenance and equipment inspection solutions. Conversely, the semiconductors and electronics industry is expected to experience the highest growth rate during the artificial intelligence in manufacturing industry forecast period.

Artificial Intelligence in Manufacturing Market Regional Outlook

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Artificial Intelligence in Manufacturing Market Regional Analysis

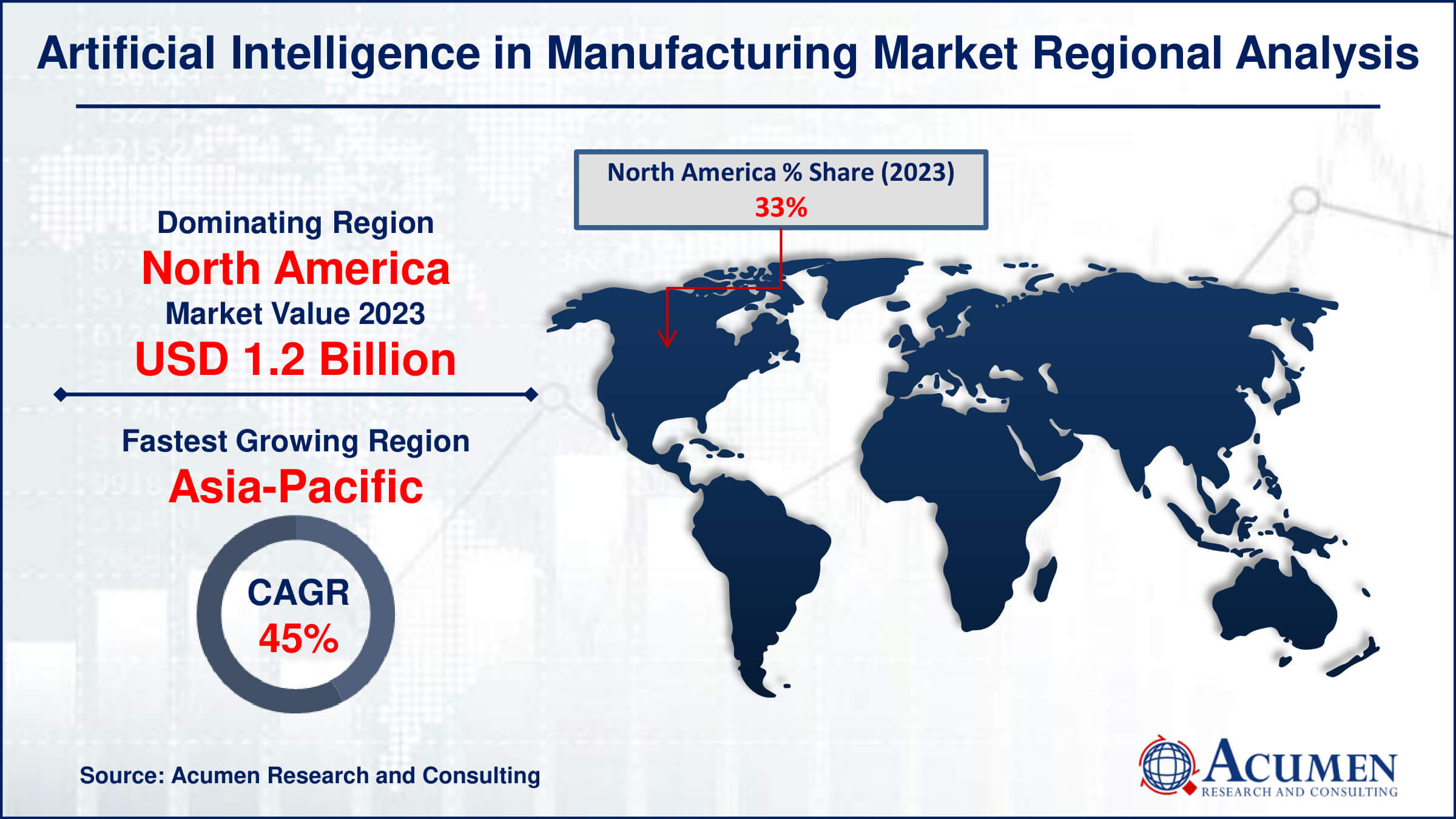

In terms of artificial intelligence in manufacturing market analysis, North America is anticipated to the largest in the globally. This dominance is driven by the escalating investments made by companies to modernize their manufacturing facilities. Additionally, North America's early adoption of cutting-edge technologies such as IoT, machine learning, and factory automation further fuels this growth trajectory. This proactive approach towards technological advancement positions North America as a key player in the global artificial intelligence in manufacturing landscape.

Concurrently, the regional outlook of the worldwide industry indicates that the Asia-Pacific region has emerged as the fastest growing region and it is expected grow over the artificial intelligence in manufacturing market forecast period, boasting substantial revenue. This growth can be attributed to the rapid deployment of automation and industrial robots across manufacturing plants, particularly in China. This trend is incentivizing manufacturers to increasingly opt for AI-based technologies, aimed at enhancing overall productivity and minimizing downtime.

Artificial Intelligence in Manufacturing Market Players

Some of the top artificial intelligence in manufacturing companies offered in our report includes Amazon Web Services, Bosch, Cisco Systems, Foxconn General Electric Company, Google, Inc., IBM Corporation, Intel, Inc., Microsoft Corporation, Nvidia Corporation, Rockwell Automation, SAP SE, and Siemens AG.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

January 2023

June 2023

October 2024

August 2020