February 2024

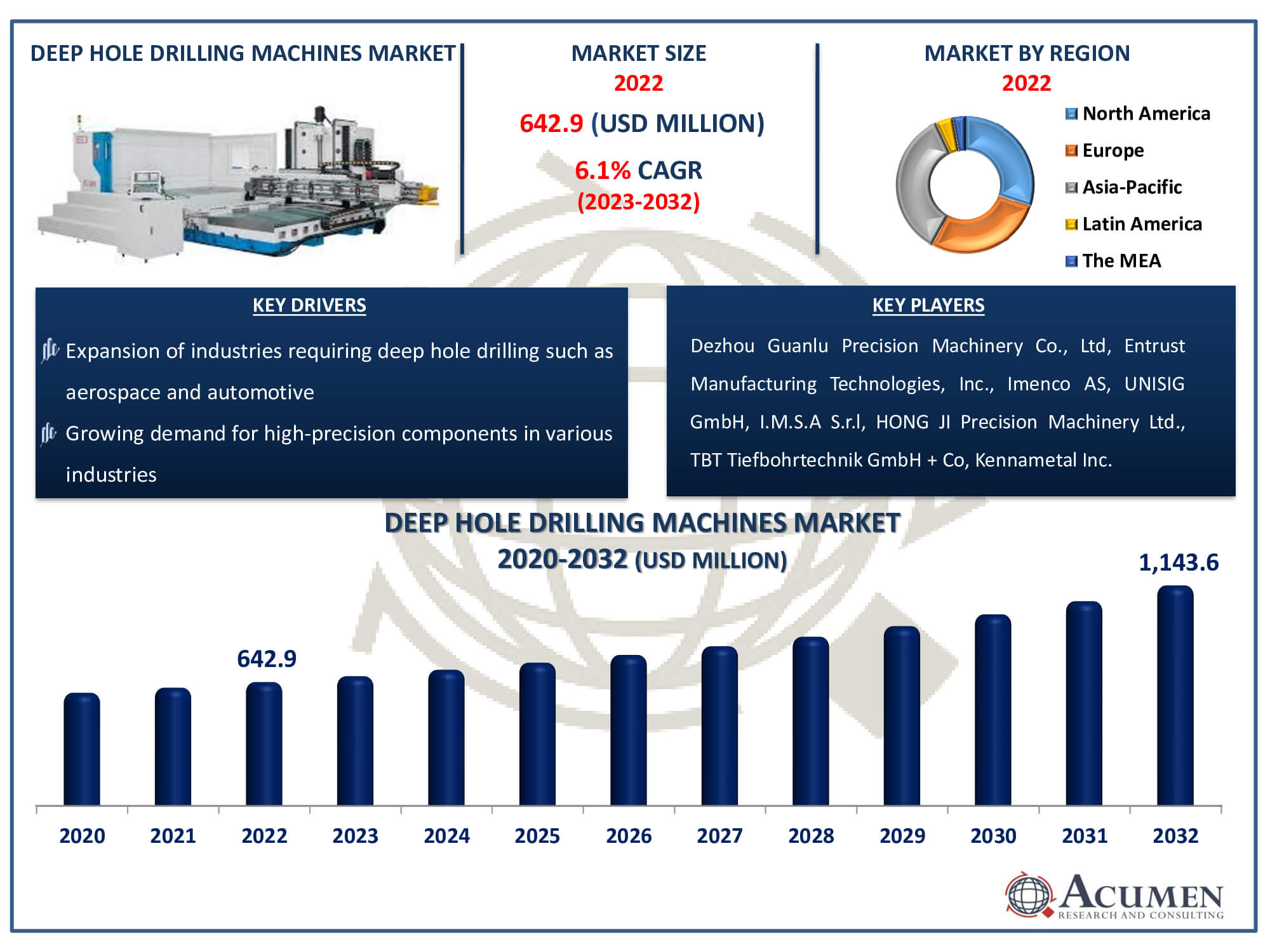

Deep Hole Drilling Machines Market Size accounted for USD 642.9 Million in 2022 and is estimated to achieve a market size of USD 1,143.6 Million by 2032 growing at a CAGR of 6.1% from 2023 to 2032.

The Deep Hole Drilling Machines Market Size accounted for USD 642.9 Million in 2022 and is estimated to achieve a market size of USD 1,143.6 Million by 2032 growing at a CAGR of 6.1% from 2023 to 2032.

Deep Hole Drilling Machines Market Highlights

A deep hole drilling machine is a metal-cutting device capable of drilling highly precise holes into almost any metal. These machines enable the use of specific tools such as gun drills and BTA to enhance deep hole drilling operations in manufacturing. They are designed to incorporate the technology employed by these tools and optimize all aspects of the process, allowing for the drilling of deep holes with accuracy, reliability, and efficiency. Deep hole drilling equipment is suitable for a variety of sizes, depths, and production rates, making them essential for holes with a depth-to-diameter ratio of 20:1 or greater.

Global Deep Hole Drilling Machines Market Dynamics

Market Drivers

Market Restraints

Market Opportunities

Deep Hole Drilling Machines Market Report Coverage

| Market | Deep Hole Drilling Machines Market |

| Deep Hole Drilling Machines Market Size 2022 | USD 642.9 Million |

| Deep Hole Drilling Machines Market Forecast 2032 | USD 1,143.6 Million |

| Deep Hole Drilling Machines Market CAGR During 2023 - 2032 | 6.1% |

| Deep Hole Drilling Machines Market Analysis Period | 2020 - 2032 |

| Deep Hole Drilling Machines Market Base Year |

2022 |

| Deep Hole Drilling Machines Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Type, By Operation, By Business Type, By End-User, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Dezhou Guanlu Precision Machinery Co., Ltd, Entrust Manufacturing Technologies, Inc., Imenco AS, UNISIG GmbH, I.M.S.A S.r.l, HONG JI Precision Machinery Ltd., TBT Tiefbohrtechnik GmbH + Co, Kennametal Inc., Loch Präzisions Bohrtechnik GmbH, Mollart Engineering Ltd., and TIBO Tiefbohrtechnik GmbH |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Deep Hole Drilling Machines Market Insights

Technological developments are driving the deep hole drilling machines market, encouraging creativity and improving the capabilities of these machining instruments. Modern technologies have been included as a result of ongoing research and development, increasing the deep hole drilling machines' productivity, accuracy, and speed. This not only meets the need for highly accurate parts in a variety of industries, but it also establishes these devices as essential resources in the dynamic production world. A further factor propelling the market is the rising need for high-precision components in sectors like medical devices, automotive, and aerospace. Given its unmatched capacity to drill lengthy, accurate holes in a variety of metals, deep hole drilling machines are becoming more and more necessary as these industries work to improve the quality and performance of their products.

However, the large initial capital outlay necessary to purchase and deploy deep hole drilling equipment poses a serious barrier to the industry. Because of the high expenses associated with the complex technology and precision necessary, these devices are not as accessible to smaller businesses. This financial barrier, despite their clear benefits, makes mass adoption difficult and could hinder market growth in deep hole drilling machines market forecast period, particularly for organizations with tight budgets.

Increased automation adoption, advancements in manufacturing processes, as well as the growing need to improve end-product quality and achieve high productivity are expected to provide lucrative growth opportunities for deep hole drilling machines market participants.

Auto Manufacturing Benefits From Deep Hole Drilling

The auto industry's future is intriguing but uncertain. Nobody knows how completely, or quickly electric vehicles will replace diesel and gasoline vehicles, or when it will happen in passenger cars rather than SUVs and heavy vehicles. Thus, technology developed for high-performance vehicles years ago is now becoming accepted. However, deep hole drilling is one superior manufacturing technology that enables the low-cost production of key aspects of those performance-enhancing automotive parts. Liquid sodium flows and draws heat from the valve head through holes drilled the length of the valve stem in sodium-filled valves, for example. Precision deep hole drilling procedures can be used to create hollow and energy-efficient camshafts. As a result, the main drivers of deep hole drilling machine design are flexibility and spindle utilization.

Deep Hole Drilling Machines Market Segmentation

The worldwide market for deep hole drilling machines is split based on type, operation, business type, end-user, and geography.

Deep Hole Drilling Machines Types

Based on the type, the BTA machines segment is expected to have the largest market share in the market over the deep hole drilling machines industry forecast period. BTA drilling employs a specialized drilling tool attached to a long drill tube to create deep holes in metal, with diameters ranging from 20 mm [0.80 in] and up to depth-to-diameter ratios of 400:1. BTA drilling is considered the most efficient method for drilling deep holes because it is cleaner, more reliable, and more capable than regular twist drills. It can achieve larger diameters and higher feed rates compared to gun drilling. Furthermore, due to the tool design, more efficient chip exhaust, and machine design and power, BTA drilling can achieve drill rates 5-7 times faster than gun drilling at the same diameter.

Deep Hole Drilling Machines Operations

According to deep hole drilling machines industry analysis, CNG operation is the largest segment CNC drilling is a machining process that utilizes a rotating cutting tool to create round holes in a stationary workpiece. These holes are typically drilled to accommodate machine screws or bolts used in assembly. Drilling machines equipped with CNC technology can produce holes with extremely close tolerances to the original design file. Furthermore, CNC drilling units can be used on a variety of materials, including metal, plastic, and natural materials. Additionally, they have the capability to create various types of holes by accommodating multiple drill bits.

Deep Hole Drilling Machines Business Types

Original equipment manufacturer (OEM) means that the parts are manufactured by the same company that produces the machine. In contrast, aftermarket parts are produced by a different company and are often designed to be compatible with as many different products and models as possible. Aftermarket parts may not always fit as well as OEM parts due to design differences and sizing errors. One reason aftermarket parts are less expensive is that they are not always made of the same high-quality materials as OEM parts. These inferior materials can lead to failures in aftermarket parts, thus driving the market for OEMs.

Deep Hole Drilling Machines End-Users

In terms of deep hole drilling machines market analysis, the automotive segment is growing rapidly due to the increased demand for precise machining in the production of various vehicle components. In the production of vital components like engine blocks, gearbox shafts, airbag propellant chambers and camshafts, deep hole drilling machines are essential. The deep hole drilling technique is becoming more widely used in the automotive industry due to its emphasis on efficiency, accuracy, and innovation. This has led to a significant growth in this market segment.

Deep Hole Drilling Machines Market Regional Outlook

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

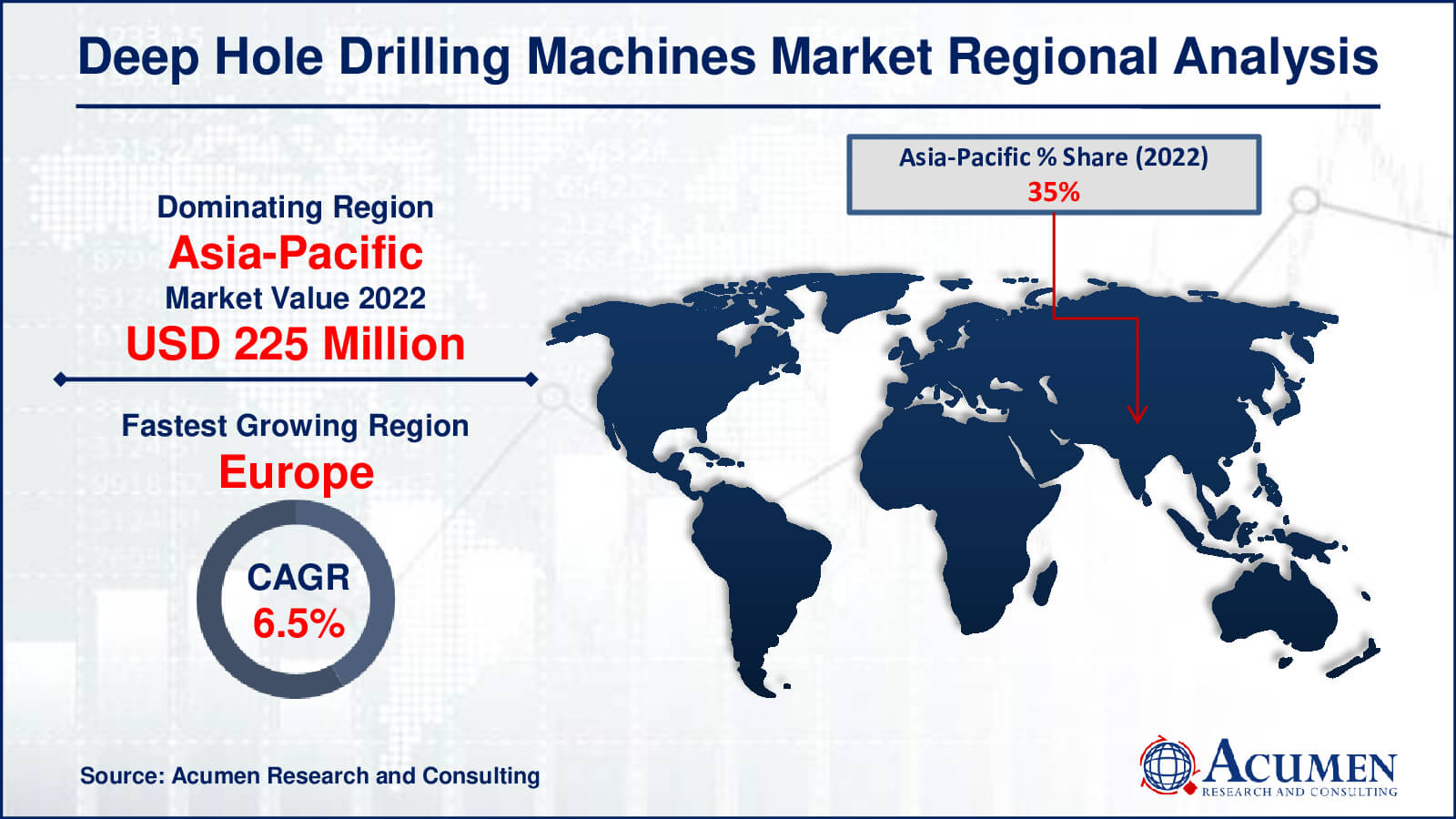

Deep Hole Drilling Machines Market Regional Analysis

Asia-Pacific is expected to grow at a significant rate during the forecast period, maintaining its dominant position in 2022 as the largest consumer of deep hole drilling and the industry leader in the entire deep hole drilling industry. Furthermore, the significant growth in the automotive industry across the Asia Pacific is one of the key factors influencing market growth. However, deep hole drilling machines are widely used in the manufacturing of various automotive components, such as camshafts, airbag propellant chambers, engine blocks, and transmission shafts. Additionally, in the medical industry, the widespread use of drilling machines in the fabrication of titanium and surgical-grade healthcare and surgical equipment is propelling market growth. After Asia-Pacific Europe is fastest growing in the market.

Deep Hole Drilling Machines Market Players

Some of the top deep hole drilling machines companies offered in our report includes Dezhou Guanlu Precision Machinery Co., Ltd, Entrust Manufacturing Technologies, Inc., Imenco AS, UNISIG GmbH, I.M.S.A S.r.l, HONG JI Precision Machinery Ltd., TBT Tiefbohrtechnik GmbH + Co, Kennametal Inc., Loch Präzisions Bohrtechnik GmbH, Mollart Engineering Ltd., and TIBO Tiefbohrtechnik GmbH.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

February 2024

June 2023

October 2024

April 2025