January 2024

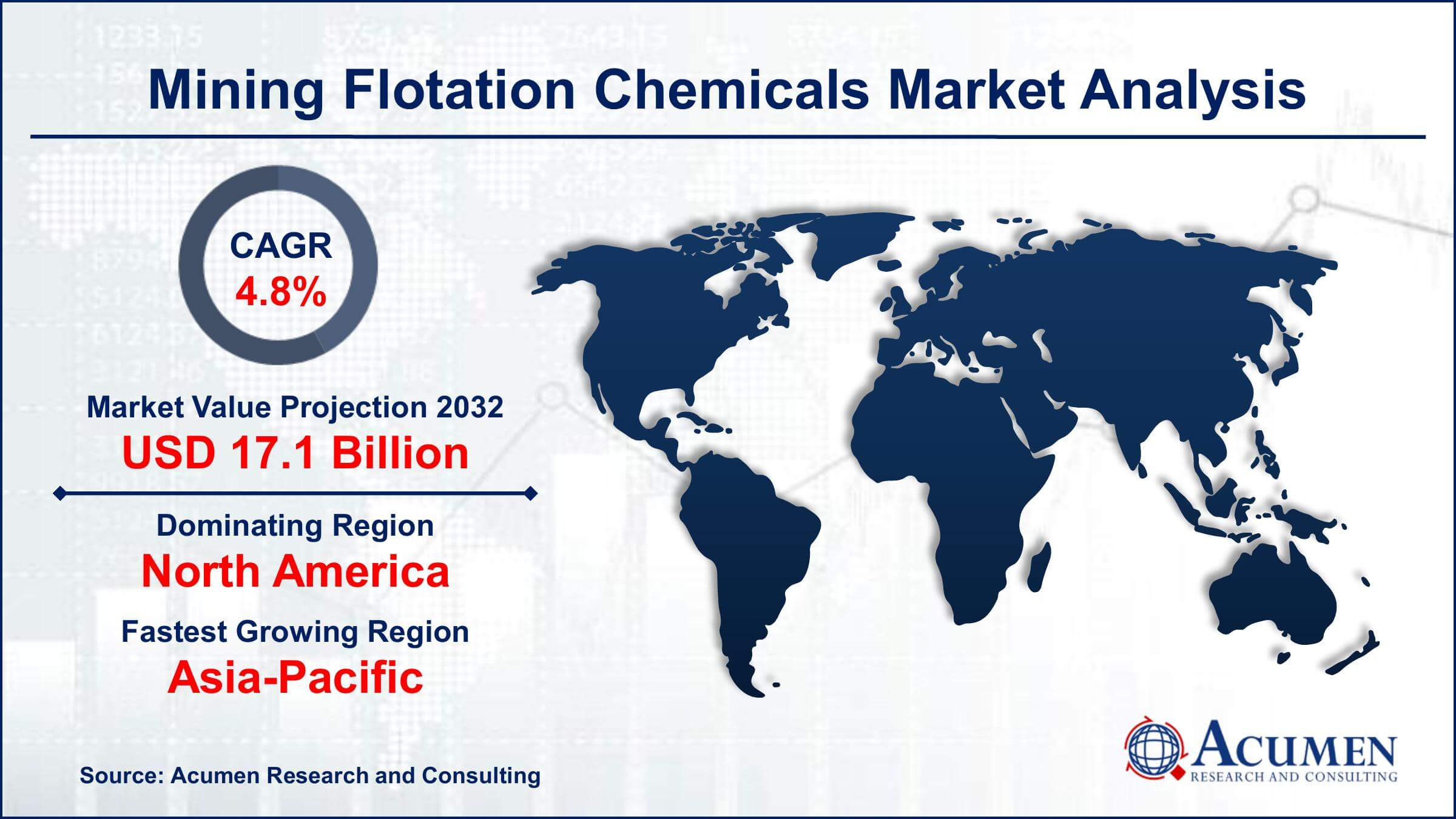

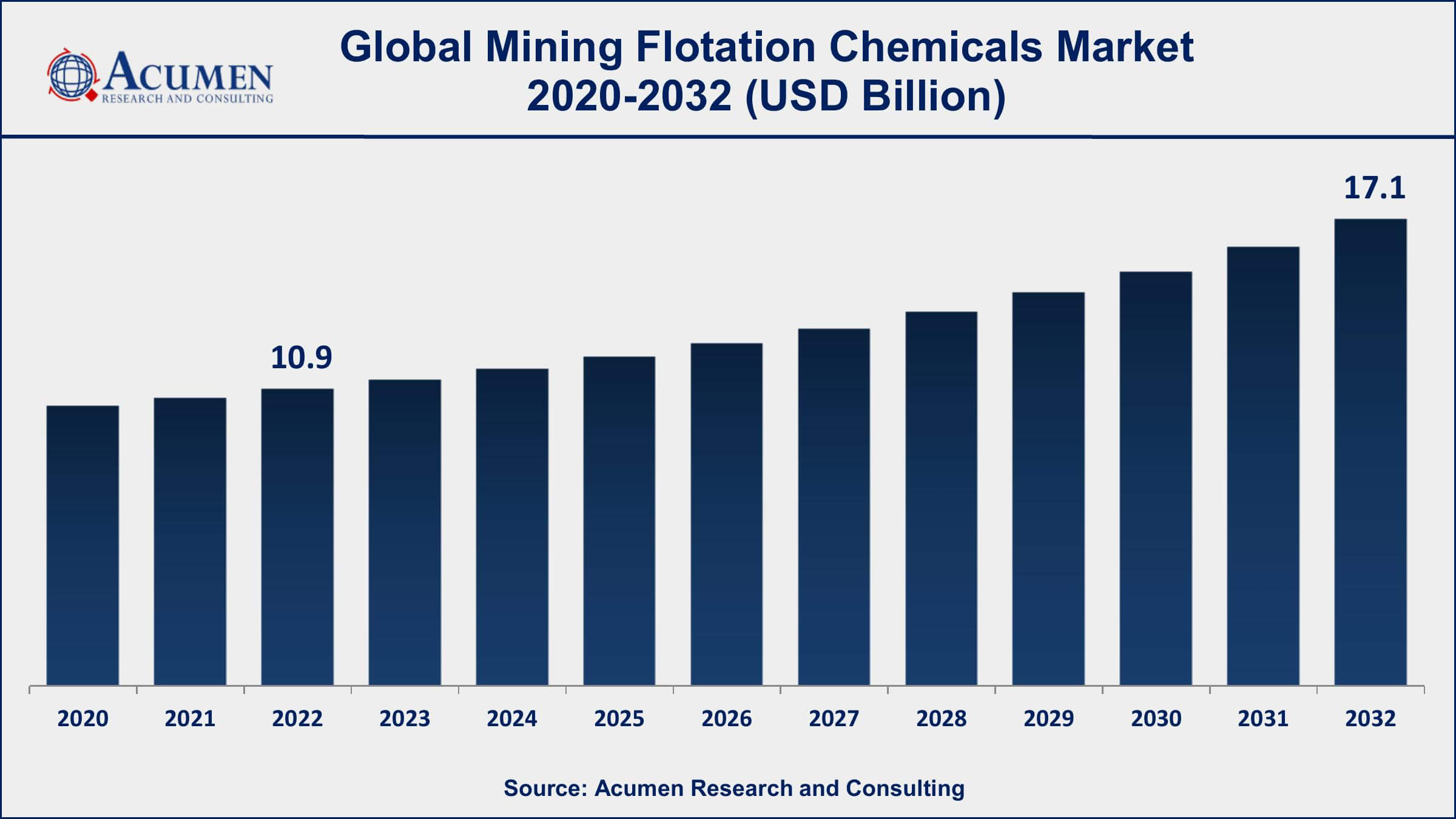

Mining Flotation Chemicals Market Size accounted for USD 10.9 Billion in 2022 and is projected to achieve a market size of USD 17.1 Billion by 2032 growing at a CAGR of 4.8% from 2023 to 2032.

The Global Mining Flotation Chemicals Market Size accounted for USD 10.9 Billion in 2022 and is projected to achieve a market size of USD 17.1 Billion by 2032 growing at a CAGR of 4.8% from 2023 to 2032.

Mining Flotation Chemicals Market Highlights

Mining flotation chemicals are specialized chemical compounds used in the process of mineral separation in mining operations. Flotation is a technique widely employed in the mining industry to extract valuable minerals from their ore through a series of physical and chemical reactions. These chemicals aid in creating a froth layer on the surface of the ore slurry, which allows for the selective attachment of specific minerals to air bubbles. This enables the separation of valuable minerals from the gangue (unwanted material).

The market for mining flotation chemicals has experienced significant growth in recent years. This can be attributed to several factors, including the increasing demand for minerals and metals, the depletion of high-grade ore deposits, and the need for more efficient extraction processes. As mining companies strive to maximize their operational efficiency and minimize environmental impact, the adoption of flotation techniques has become more prevalent. Furthermore, advancements in mining flotation chemicals have played a crucial role in enhancing the efficiency of the separation process. Manufacturers are continuously developing new chemicals and formulations that offer improved selectivity, higher recovery rates, and reduced environmental impact. These chemicals are tailored to suit specific ore types and processing conditions, thereby increasing the effectiveness of mineral separation.

Global Mining Flotation Chemicals Market Trends

Market Drivers

Market Restraints

Market Opportunities

Mining Flotation Chemicals Market Report Coverage

| Market | Mining Flotation Chemicals Market |

| Mining Flotation Chemicals Market Size 2022 | USD 10.9 Billion |

| Mining Flotation Chemicals Market Forecast 2032 | USD 17.1 Billion |

| Mining Flotation Chemicals Market CAGR During 2023 - 2032 | 4.8% |

| Mining Flotation Chemicals Market Analysis Period | 2020 - 2032 |

| Mining Flotation Chemicals Market Base Year | 2022 |

| Mining Flotation Chemicals Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Ore Type, By Chemical Type, And By Geography |

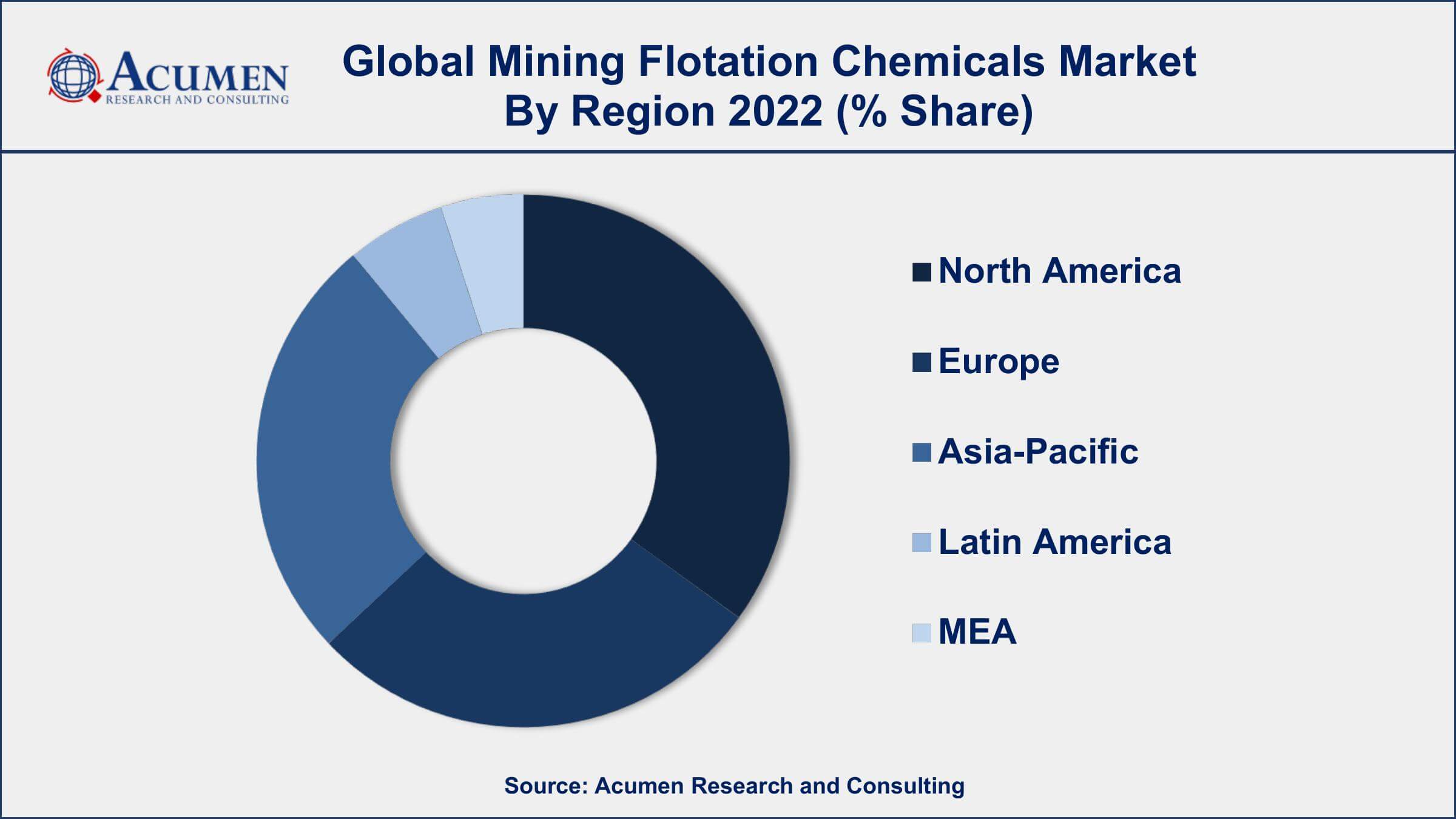

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | BASF SE, Clariant AG, Huntsman Corporation, Cheminova A/S, Cytec Industries Inc., Chevron Phillips Chemical Company, Nasaco International LLC, Kemira Oyj, and Beijing Hengju Chemical Industry Co. Ltd. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Mining flotation chemicals are specialized chemical compounds used in the process of mineral separation in mining operations. The primary application of these chemicals is in the flotation process, which is widely utilized in the mining industry to extract valuable minerals from their ore. Flotation involves the introduction of various chemicals into a mixture of finely ground ore and water, creating a froth layer on the surface. This froth selectively attaches to specific mineral particles, allowing their separation from the unwanted gangue material.

The chemicals used in mining flotation serve different purposes throughout the process. Collectors are chemicals that enhance the attachment of specific minerals to air bubbles, enabling their flotation. Frothers, on the other hand, create a stable froth layer by reducing the surface tension of the water, aiding in the formation and stabilization of air bubbles. Modifiers or depressants are chemicals that regulate the interaction between minerals, ensuring the selective separation of desired minerals. The application of mining flotation chemicals is vital for efficient mineral recovery. By utilizing different combinations and concentrations of chemicals, mining companies can achieve high recovery rates and improve the overall profitability of their operations. These chemicals are tailored to suit specific ore types, mineral compositions, and processing conditions, ensuring optimal separation and reducing the loss of valuable minerals.

The mining flotation chemicals market has been experiencing significant growth in recent years and is expected to continue expanding in the coming years. One of the key drivers for this growth is the increasing global demand for minerals and metals. As industries such as construction, automotive, and electronics continue to grow, the need for raw materials intensifies, driving the demand for mining activities and subsequently the use of flotation chemicals. Another factor contributing to the market's growth is the depletion of high-grade ore deposits. As accessible high-grade ores become scarcer, mining companies are increasingly focusing on the extraction of lower-grade ores. Flotation processes, aided by flotation chemicals, offer an efficient method for separating valuable minerals from such ores. The adoption of flotation techniques enables the extraction of minerals that were previously considered economically unviable, thus driving the demand for flotation chemicals.

Mining Flotation Chemicals Market Segmentation

The global Mining Flotation Chemicals Market segmentation is based on ore type, chemical type, and geography.

Mining Flotation Chemicals Market By Ore Type

In terms of ore types, the sulfide ore segment has seen significant growth in the recent years. Sulfide ores are a primary source of many valuable metals, including copper, lead, zinc, nickel, and gold. These ores typically contain sulfide minerals, such as chalcopyrite, sphalerite, galena, and pyrite, which require effective flotation processes for efficient extraction. As a result, the demand for flotation chemicals specific to sulfide ores has been steadily increasing. One of the key drivers for the growth of the sulfide ore segment is the rising global demand for base metals. These metals are extensively used in various industries, such as construction, manufacturing, and infrastructure development. As urbanization and industrialization continue to expand worldwide, the demand for base metals derived from sulfide ores remains strong. This drives the need for efficient and effective flotation processes, supported by appropriate flotation chemicals, to extract and recover these valuable metals from sulfide ores.

Mining Flotation Chemicals Market By Chemical Type

According to the mining flotation chemicals market forecast, the collectors segment is expected to witness significant growth in the coming years. Collectors are chemical reagents that facilitate the attachment of air bubbles to mineral particles, enabling their separation from the gangue material during the flotation process. They play a crucial role in improving the selectivity and efficiency of mineral flotation. The growth of the collectors segment is primarily driven by the increasing demand for specific minerals, such as copper, gold, and silver. These minerals are widely used in various industries, including electronics, construction, and jewelry. As the demand for these minerals continues to rise, mining companies are investing in advanced flotation processes, supported by specialized collectors, to maximize mineral recovery rates. This drives the demand for collectors in the mining flotation chemicals market. Furthermore, the development of innovative collector formulations is contributing to the growth of this segment.

Mining Flotation Chemicals Market Regional Outlook

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Mining Flotation Chemicals Market Regional Analysis

Geographically, North America dominates the mining flotation chemicals market in 2022. North America is rich in mineral resources, including vast deposits of base metals, precious metals, and industrial minerals. The mining industry in North America, particularly in countries like the United States and Canada, has a long-standing history and is well-established. This provides a solid foundation for the demand and consumption of mining flotation chemicals. Moreover, North America has a strong emphasis on technological advancements and innovation in the mining sector. The region is home to several leading mining companies and chemical manufacturers that invest heavily in research and development to develop advanced flotation chemicals and processes. This focus on innovation allows for the continuous improvement of flotation techniques, leading to higher efficiency and better recovery rates. The availability of cutting-edge technologies and expertise in the region further contributes to the dominance of North America in the mining flotation chemicals market.

Mining Flotation Chemicals Market Player

Some of the top mining flotation chemicals market companies offered in the professional report include BASF SE, Clariant AG, Huntsman Corporation, Cheminova A/S, Cytec Industries Inc., Chevron Phillips Chemical Company, Nasaco International LLC, Kemira Oyj, and Beijing Hengju Chemical Industry Co. Ltd.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

January 2024

April 2021

July 2022

December 2023