October 2024

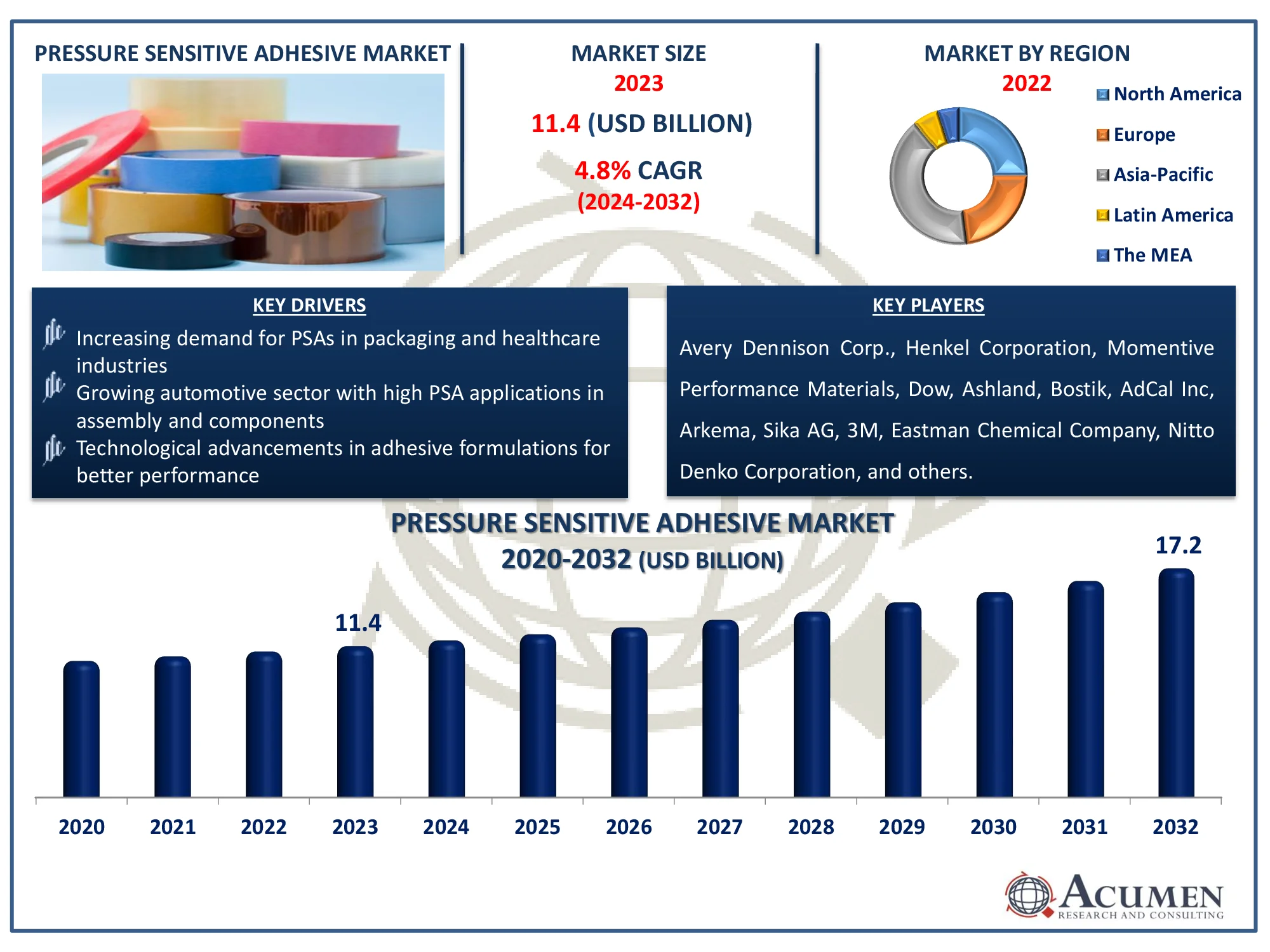

The Global Pressure Sensitive Adhesive Market Size accounted for USD 11.4 Billion in 2023 and is estimated to achieve a market size of USD 17.2 Billion by 2032 growing at a CAGR of 4.8% from 2024 to 2032.

The Global Pressure Sensitive Adhesive Market Size accounted for USD 11.4 Billion in 2023 and is estimated to achieve a market size of USD 17.2 Billion by 2032 growing at a CAGR of 4.8% from 2024 to 2032.

Pressure Sensitive Adhesive Market Highlights

Pressure-sensitive adhesives are those that adhere to a variety of substrates when applied pressure. Pressure-sensitive adhesives are typically coupled via polar attraction at the substratum surface. Press-sensitive adhesives are manufactured using a variety of adhesive methods, including solvent and thermal melting. Adhesives are suspended in solvent-based structures, whereas thermoplastic rubber is mixed with oils, tackling agents, and antioxidants in warm melts. Pressure-sensitive adhesives are viscous and not stable, so they remain sticky and can moisten touch surfaces.

The packaging industry's increased need will drive the pressured adhesive markets. The device offers several benefits, including rapid binding, adaptability, and user friendliness, which increases demand in logistics. PSA bonds to a wide range of substrates and coatings, and manufacturers keep up with the latest packaging innovations. PSAs, as an alternative to bolts, rivets, and other fasteners, are increasingly being employed in cars. This is done to speed up and simplify the installation of the car's fluid adhesive. Other product benefits include the use of thinner and lighter materials, a shorter installation time, minimal surface finishing requirements, cost savings, etc. It can link many items without incompatibility. The item has a variety of end consumers.

Global Pressure Sensitive Adhesive Market Dynamics

Market Drivers

Market Restraints

Market Opportunities

Pressure Sensitive Adhesive Market Report Coverage

|

Market |

Pressure Sensitive Adhesive Market |

|

Pressure Sensitive Adhesive Market Size 2023 |

USD 11.4 Billion |

|

Pressure Sensitive Adhesive Market Forecast 2032 |

USD 17.2 Billion |

|

Pressure Sensitive Adhesive Market CAGR During 2024 - 2032 |

4.8% |

|

Pressure Sensitive Adhesive Market Analysis Period |

2020 - 2032 |

|

Pressure Sensitive Adhesive Market Base Year |

2023 |

|

Pressure Sensitive Adhesive Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Product, By Adhesive Chemistry, By Technology, By End-Use, and By Geography |

|

Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Avery Dennison Corp., Henkel Corporation, Dow, Momentive Performance Materials, Ashland, Bostik, AdCal Inc, Arkema, Sika AG, 3M, Eastman Chemical Company, Nitto Denko Corporation, tesa Tapes, and H.B. Fuller Company. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Pressure Sensitive Adhesive Market Insights

As the automotive and electronics industries expand swiftly, the global pressure sensitive adhesive (PSA) market may emerge. Increased regulatory pressure to improve kilometric throughput, lightweight and low vehicle emissions will drive the demand for lightweight automotive apps. Most are pressured using adhesives that are sensitive to pressure. The market for pressured adhesives is predicted to expand due of electronic device miniaturization. Pressure-sensitive adhesives are utilized in a wide range of industries, including packaging, footwear, construction, automotive, and electronics. In the following years, the emphasis may be on growing the product portfolio and application base. PSA market has grown significantly as a result of high demand from the packaging and labeling sectors. Further increases in RFID labels were predicted to boost demand for pressure-sensitive labels, which play an important role in inventory management.

The primary reason for this is that RFID labels are wireless non-contact tags that are widely employed in a variety of end-use sectors such as medical, packaging, architecture, and automotive. Regulatory requirements to enhance mileage efficiency and reduce vehicle emissions in automotive applications have expanded the use of pressure-sensitive adhesives. Stringent power efficiency legislation, expanding public health risks, and growing environmental difficulties involving GHG emissions will all have an impact on market development as the capability of pressured adhesives in labeling increases. This growing demand leads to increase market growth.

The worldwide pressure sensitive adhesive (PSA) market is primarily driven by product innovation and development in the flexible packaging market. Other factors expected to support market expansion include the miniaturization of electrical products and advancements in radio frequency detection (RFID) and radio scope labels in the medical sector. Increased automobile manufacturing and a greater emphasis on vehicle weight reduction are driving Asia-Pacific's prescribed adhesive industry. Regulatory requirements to enhance mileage efficiency and reduce vehicle emissions in automotive applications have expanded the use of pressure-sensitive adhesives. Stringent power efficiency legislation, increased public health risks, and developing environmental challenges related to GHG emissions will all have an impact on market development as the capacity of pressured adhesives in labeling and automotive applications grows.

Current product advancements should broaden the scope of pressurized adhesives in structural applications in order to increase elasticity and rigidity modules. However, fluctuations in raw material prices and stringent governmental regulations on volatile organic compound (VOC) emissions limit the pressure sensitive adhesive (PSA) market growth. The increased use of bio-based pressure sensitive adhesives, as well as developments in stress-sensitive adhesive tapes, is expected to generate significant market expansion potential.

Pressure Sensitive Adhesive Market Segmentation

The worldwide market for pressure sensitive adhesive is split based on product, adhesive chemistry, technology, end-use, and geography.

Pressure Sensitive Adhesives Market By Product

According to the pressure sensitive adhesive industry analysis, tapes are the most popular product in the market due to its diverse applications in industries such as packaging, automotive, electronics, and construction. Their ease of use, durability, and ability to attach to a variety of surfaces without the use of heat or water make them extremely popular. Furthermore, advances in adhesive technology have increased the performance of PSA tapes, increasing their strength and temperature resistance. Tapes' adaptability positions them as a significant driver of PSA market growth.

Pressure Sensitive Adhesives Market By Chemistry

According to the pressure sensitive adhesive industry analysis, acrylic adhesive chemistry has dominated the market due to its good combination of adhesion, flexibility, and resilience to environmental conditions such as UV light, temperature, and age. Acrylic-based PSAs form strong, long-lasting bindings on a wide range of surfaces, making them appropriate for industries like automotive, healthcare, and electronics. Their adaptability and durability in both permanent and removable applications help to explain their widespread use.

Pressure Sensitive Adhesives Market By Technology

According to the pressure sensitive adhesive market forecast, water-based technology is the largest product segment in terms of sales at the forecast time. Water-based stickers are suitable for a variety of applications such as graphics, labels, and adhesives. It adheres well to a variety of surfaces, has excellent die-cutting capabilities, is water resistant, and is suitable for speed coating. In optical applications, solvent-based technology is most commonly used. Tackers, solvents, polymers, and other components are dissolved together. The solvent-based PSA's raw components are oil products, which are more expensive than other classes.

Pressure Sensitive Adhesives Market By End-Use

According to the pressure sensitive adhesive market forecast, packaging is the largest end-user category that is expected to grow during the forecast period. It allows swiftly bonding different materials and improving the appearance of an item. Ongoing developments in packaging industry further become drivers for segment’s growth. For instance, in April 2024, the cyclos-HTP Institute (CHI) certified Henkel's Aquence PS 3017, an adhesive solution. This accreditation indicates that the packaging components are recyclable. Such developments are crucial as businesses seek to meet environmental regulations and consumer expectations for sustainable packaging solutions. Moreover, another important sector in the industry, electronics and laminates, is expected to grow at a significant CAGR in PSA market over the projection period.

Pressure Sensitive Adhesive Market Regional Outlook

North America

Asia-Pacific

Latin America

The Middle East & Africa

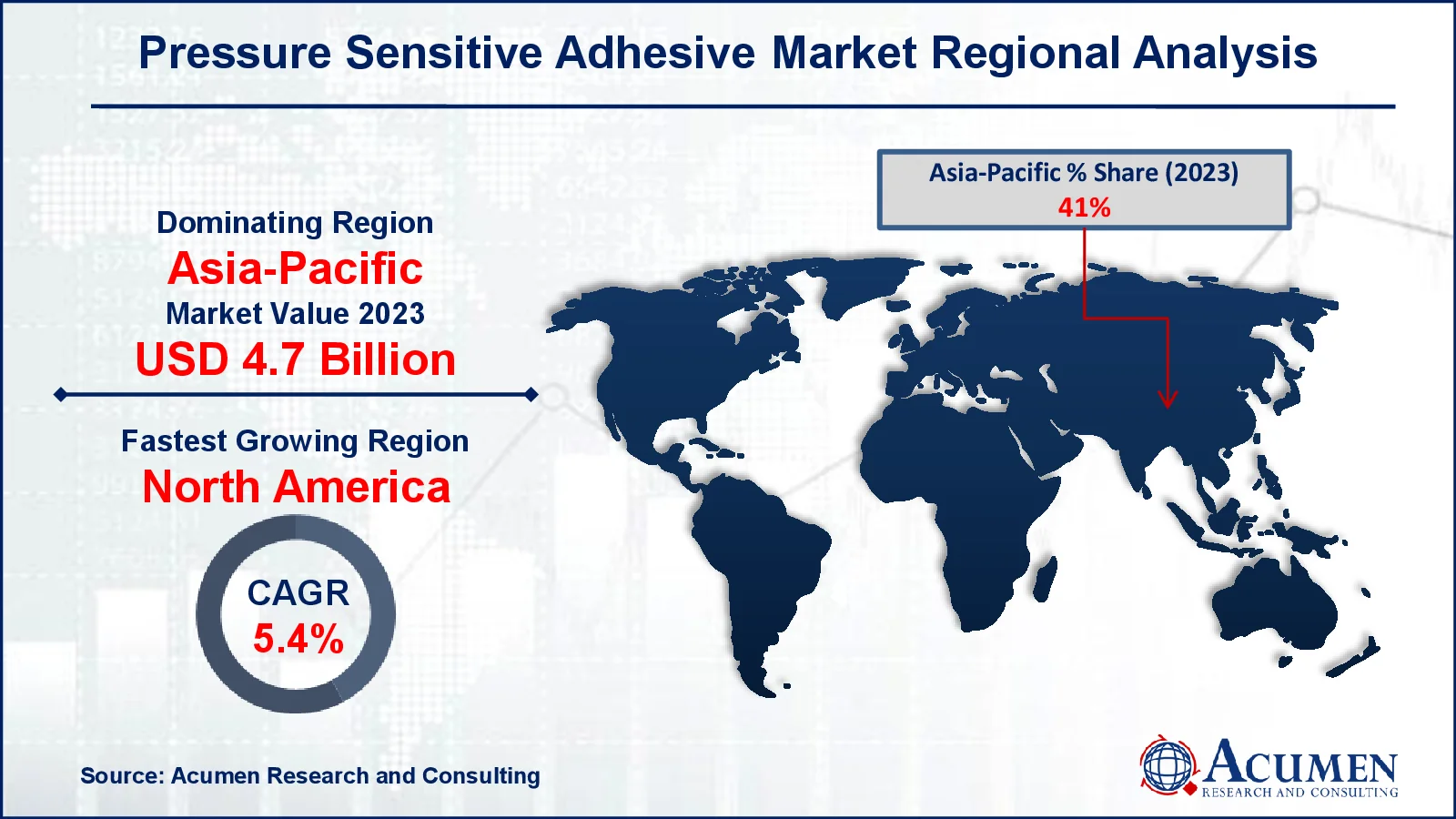

Pressure Sensitive Adhesive Market Regional Analysis

For several reasons, Asia-Pacific represents the world's largest pressure sensitive adhesive (PSA) market for pressured adhesives. The wealthy middle class is growing, as is consumerism in developing countries like China, India, and Korea. Because of increased industry and infrastructural development, Asia-Pacific is the largest country section of the PSA market. India, South Korea, China, and Indonesia have been increasing their need for pressured adhesives as key customers in Asia-Pacific, as well as PSA producers.

The rapid growth of automobiles and electronics is expected to propel the regional market in the near future. Increased demand is expected to improve market revenues for mobilizes, stationary, footwear, and consumer products. These variables have risen as a result of advancements in developing countries like India, China, and Japan. Another factor driving market growth could be an increase in demand for silicone-based adhesives. Increased expansion of health infrastructure, as well as the involvement of the medical industry, could also enhance market growth.

In the future years, North America might become the world's second largest economy. The market for pressurized sensitive adhesives is expected to remain profitable in North America and Europe, owing mostly to severe VOC emission regulations combined with fuel efficiency norms. A regulator such as REACH and the US to improve sustainability, the EPA has implemented stringent laws to protect the chemical industries, resulting in increased demand for adhesives that meet pressure-sensitive criteria.

Pressure Sensitive Adhesive Market Players

Some of the top pressure sensitive adhesive companies offered in our report include Avery Dennison Corp., Henkel Corporation, Dow, Momentive Performance Materials, Ashland, Bostik, AdCal Inc, Arkema, Sika AG, 3M, Eastman Chemical Company, Nitto Denko Corporation, tesa Tapes, and H.B. Fuller Company.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

October 2024

March 2024

December 2021

March 2024