September 2023

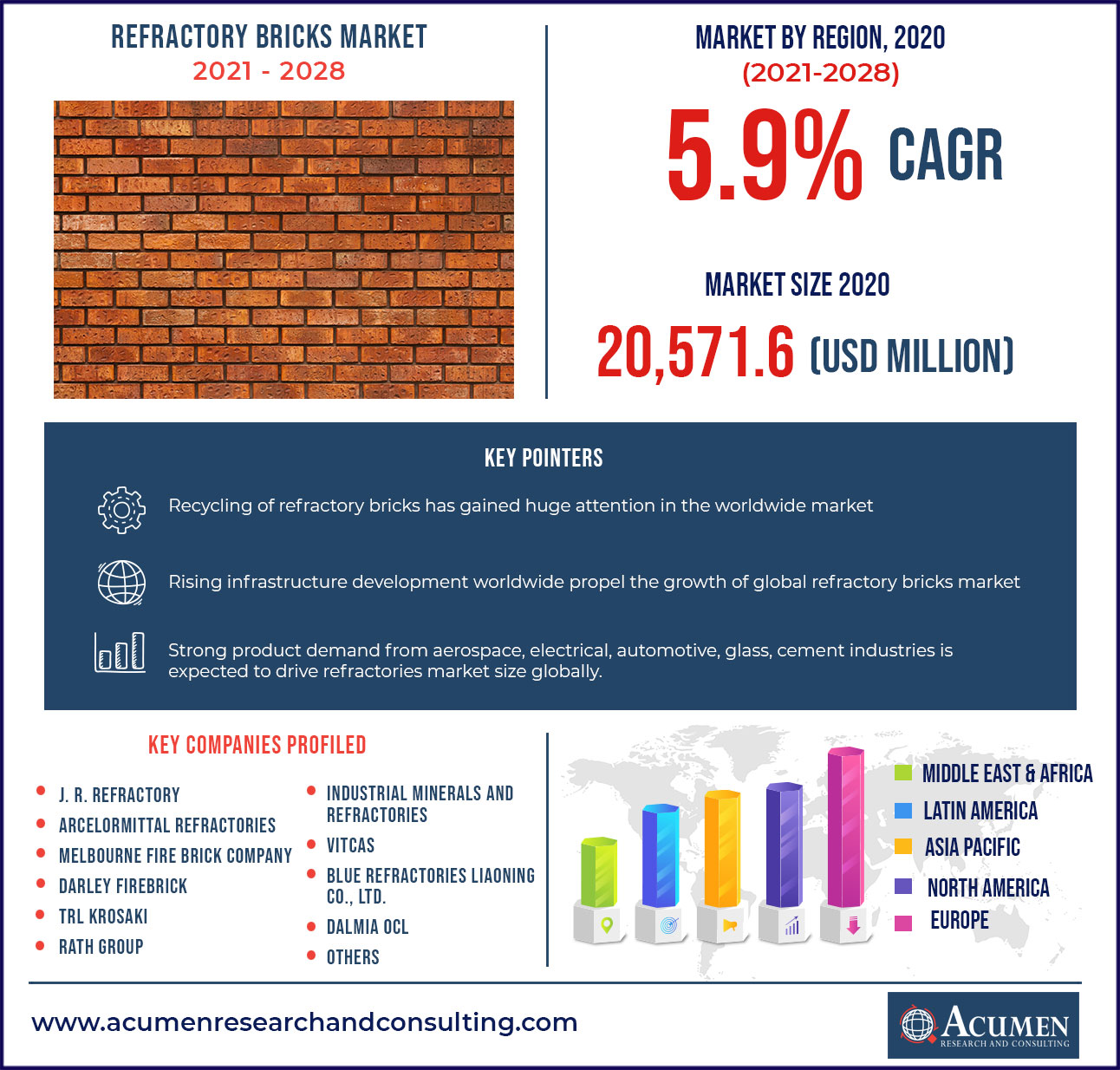

Refractory Bricks Market Accounted US$ 20,571.6 Mn In 2020 With CAGR Of 5.9% During The Analysis Period Of 2021 To 2028 And Anticipated To Reach US$ 32,541.4 Mn By 2028

The global refractory bricks market accounted US$ 20,571.6 Mn in 2020 by recording significant CAGR of 5.9% during the analysis period of 2021 to 2028.

Refractory brick is defined as a block of ceramic material specially designed for utilization in kilns, furnaces, lining, fireboxes, and fireplaces. Additionally, it can withstand very high temperature for up to 16490C with low thermal conductivity for greater energy efficiency. Further, basic refractory bricks are composed of magnesite brick (comprising of 85% magnesium oxide + 35% iron oxide) and dolomite refractory bricks (that can resist temperature at 14000C to 16000C temperature).

Report coverage

| Market | Refractory Bricks Market |

| Analysis Period | 2017 - 2028 |

| Base Year | 2020 |

| Forecast Data | 2021 - 2028 |

| Segments Covered | By Type, By Application, By Material, and By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | J. R. Refractory, ArcelorMittal Refractories, Melbourne Fire Brick Company, Darley Firebrick, TRL Krosaki, Rath Group, Industrial Minerals and Refractories, Vitcas, Blue Refractories Liaoning Co., Ltd., Dalmia OCL, and among others |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Regulation Analysis |

| Customization Scope |

10 hrs of free customization and expert consultation |

Market Trends:

Recycling of refractory bricks has gained huge attention in the worldwide market

Refractory are indispensable for all high temperature processes, involving production of metals, cement, glass, and ceramics. Additionally, refractory production is around 35-40 million tons per year, with annual fluctuations determined largely by the iron and steel industry responsible for 70% of the total demand. During this phase, 30-40% of the refractory is consumed pinpointing up to 28 million tons of spent refractory generated every year. From the past two decades, recycling of spent refractory has started to emerge as a growing trend owing to environmental favorability and rising cost for land filling. Therefore, with rising pricing and supply issues for high quality virgin raw materials have imposed pressure for closed-loop refractory recycling; the interest for recycling within the refractory production industry is rising at a tremendous pace.

Rising infrastructure development worldwide propels the growth of global refractory bricks market

Rising demand especially for the construction of new buildings is likely to bolster the demand for refractory bricks in the coming years. As refractory production is strongly dependant on high quality raw materials, many of these are becoming center of attraction for construction of new building. Additionally, tremendous growth witnessed in the construction activity fuel the demand for the production of iron and steel globally particularly in developing economies. Also, the rising use of iron and steel in the automobile sector further propel the demand for refractory bricks in the market. Some of these major applications for refractory bricks in these sectors include usage in internal lining of furnaces to make iron and steel, in furnaces for heating steel before further processing, in vessels for holding and transporting metal and slag, and in the flues or stacks through which hot gases are conducted. For instance, according to the report released by the World Steel Association, the global demand for steel has reached about 1.76 million metric ton in 2019, and is anticipated to reach 1.81 million tons by 2021, with a growth of about 1.7%. Furthermore, architects have exposed the utilization of refractory bricks to build and coat surfaces.

Key takeaway:

Reprocessed polyolefin water sachet waste, commonly called "pure water" sachet has been strongly investigated and declared as a new porosity inducing material for the manufacturing of insulating refractory bricks. Used polyolefin sachet were chemically treated and recrystallized into powder of varying particle size and the powder has been found to burn readily without a residue. This prominent characteristic is considered ideal for porosity material for the manufacturing of insulating refractory bricks and some preliminary studies have been conducted. As bricks were composed with varying proportion of the new material and the bulk density, shrinkage and thermal conductivity were determined and compared with those of the bricks composed from sawdust and naphthalene that are the common conventional porosity materials. Therefore, this new material is found to compare favorably well, and in some cases, better than the conventional materials.

Market Segmentation

The global refractory bricks market is segmented based on type, application, and material. Based on type, the market is bifurcated into unshaped and shaped. By application, the market is segregated as furnaces, metallurgy, kilns, incinerators, and others. By materials, the market is segregated as alumino-silicates, silicon carbides, and ceramic bricks.

Based on type, shaped segment will hold dominating share for the overall market. Shape refractory is those refractory that have resistance to corrosive reactions that are chemically basic slags, dusts and fumes at elevated temperatures. Additionally, shape refractory is characterized by an extremely high refractoriness and good resistance to basic slags. The chemical-physical characteristics make ideal refractory for steel making process. Hence, shape refractory received increase importance with the introduction of basic oxygen steel making process.

Regional Landscape

Europe records maximum share for refractory bricks market; Asia Pacific records fastest growing CAGR for the analysis period of 2021 to 2028

Among European countries, Germany is the highest contributing country for refractory bricks market accounting to US$1,368.4 Mn in 2020 revenue. The EU Publications Office report states that recycling of spent refractory constitutes an important new secondary source of refractory raw materials. In Europe, recycling refractory has increased substantially over the years. Increased recycling will also reduce the cost of raw materials and make the production of refractory material in Europe more competitive and resource efficient. On the other hand, economic and environmental assessment reveals that the REFRASORT system can meet the market demand for increasing refractory recycling with creating economic benefits for both refractory recyclers and producers by reducing environmental impact associated to refractory production at the European and global level. A substantial replication potential is possible at the European and worldwide level, for the steel industry as well as all refractory consuming industry.

Asia Pacific is set to record fastest growing CAGR for refractory bricks market in the forthcoming years. Among APAC provinces, China is the hub for alumina, bauxite, graphite, and magnesia as many countries are highly dependent on import of key refractory grade minerals. For instance, the European refractory industry relies completely on imports of raw materials, particularly high grade magnesia, bauxite, and graphite that are mainly sourced from China. This is one of the key factors that attribute for the growth of refractory bricks at regional level.

Competitive Landscape

The prominent players of the global refractory bricks market involve J. R. Refractory, ArcelorMittal Refractories, Melbourne Fire Brick Company, Darley Firebrick, TRL Krosaki, Rath Group, Industrial Minerals and Refractories, Vitcas, Blue Refractories Liaoning Co., Ltd., Dalmia OCL, and among others

Market Segmentation

Market By Type

Market By Application

Market By Material

Market By Geography

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

September 2023

April 2023

January 2025

January 2024