July 2024

Surface Technology Market Size accounted for USD 336.8 Billion in 2022 and is projected to achieve a market size of USD 539.4 Billion by 2032 growing at a CAGR of 4.9% from 2023 to 2032.

The Surface Technology Market Size accounted for USD 336.8 Billion in 2022 and is projected to achieve a market size of USD 539.4 Billion by 2032 growing at a CAGR of 4.9% from 2023 to 2032.

Surface Technology Market Highlights

Surface technology, also known as surface engineering or surface science, involves the modification and enhancement of the surface properties of materials to achieve specific performance characteristics. This field encompasses a wide range of techniques and processes, including coatings, treatments, and modifications, aimed at improving attributes such as hardness, wear resistance, corrosion resistance, and biocompatibility. Surface technology plays a crucial role in various industries, including manufacturing, automotive, aerospace, electronics, healthcare, and energy, where the performance and longevity of materials are essential.

The market for surface technology has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials in various applications. Advancements in manufacturing technologies, such as nanotechnology and additive manufacturing, have contributed to the development of innovative surface treatment methods. Additionally, the growing emphasis on sustainability and environmental concerns has led to the adoption of eco-friendly surface technologies. The automotive and aerospace industries, in particular, have been key drivers of the market, as they seek to improve fuel efficiency, reduce emissions, and enhance the durability of components. As industries continue to prioritize efficiency, durability, and sustainability, the surface technology industry is expected to witness further growth and evolution in the coming years.

Global Surface Technology Market Trends

Market Drivers

Market Restraints

Market Opportunities

Surface Technology Market Report Coverage

| Market | Surface Technology Market |

| Surface Technology Market Size 2022 | USD 336.8 Billion |

| Surface Technology Market Forecast 2032 | USD 539.4 Billion |

| Surface Technology Market CAGR During 2023 - 2032 | 4.9% |

| Surface Technology Market Analysis Period | 2020 - 2032 |

| Surface Technology Market Base Year |

2022 |

| Surface Technology Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Type, By Application, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Bodycote, Guangdong Strong Metal Technology Co., Ltd, DOWA Thermotech Co., Ltd., FPM Heat Treating, Harterei Reese, Paulo, Surface Technology, Inc., Aalberts Surface technology, Schaeffler Group, and Linde Plc. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Surface technology involves the modification and improvement of material surfaces to enhance their properties and performance. This field employs a variety of techniques such as coatings, treatments, and modifications to alter surface characteristics like hardness, wear resistance, corrosion resistance, and more. Surface technology is pivotal in extending the lifespan of materials, improving their functionality, and addressing industry-specific challenges. In terms of applications, surface technology has widespread use across various sectors. In the manufacturing industry, it is employed to enhance the durability and efficiency of components. In automotive and aerospace, surface treatments play a critical role in improving fuel efficiency, reducing friction, and increasing resistance to wear and corrosion. Additionally, surface technology finds applications in healthcare for biocompatible coatings on medical devices, in electronics for corrosion protection, and in energy for optimizing the performance of components in harsh environments. The versatility of surface technology makes it a key player in shaping the functional and performance aspects of materials across a broad spectrum of applications.

The surface technology market has been experiencing robust growth in recent years, driven by a confluence of factors that underscore its increasing importance across diverse industries. The demand for advanced surface treatments and coatings has surged as manufacturers seek to enhance the performance, durability, and efficiency of their products. Industries such as automotive, aerospace, and electronics have been at the forefront of this growth, with a particular focus on improving the wear resistance, corrosion protection, and overall functionality of critical components. Moreover, the rising trend of miniaturization in electronics and the quest for lightweight materials in automotive and aerospace applications have spurred the need for innovative surface technologies. Technological advancements play a pivotal role in propelling market growth.

Surface Technology Market Segmentation

The global Surface Technology Market segmentation is based on type, application, and geography.

Surface Technology Market By Type

In terms of types, the high velocity oxygen fuel (HVOF) coatings segment has emerged as a significant driver of growth within the surface technology market. HVOF is a thermal spray coating process that involves the high-speed combustion of gases to generate a supersonic jet of particles, which are then propelled onto the substrate surface. This technique results in coatings with exceptional density, hardness, and adhesion, making it a preferred choice for applications requiring superior wear resistance, corrosion protection, and thermal insulation. The aerospace and automotive industries have been pivotal in propelling the growth of the HVOF coatings segment, as these sectors demand high-performance materials to withstand extreme conditions and ensure the longevity of critical components. One key factor contributing to the growth of the HVOF coatings market is the increasing emphasis on lightweight materials in aerospace and automotive applications.

Surface Technology Market By Application

According to the surface technology market forecast, the automotive segment is expected to witness significant growth in the coming years. One of the key factors fueling this growth is the automotive industry's relentless pursuit of lightweight materials and fuel efficiency. Surface technologies, including coatings that improve wear resistance and reduce friction, play a crucial role in achieving these objectives. Additionally, the need for corrosion protection and aesthetic appeal has driven the adoption of advanced surface treatments in the automotive sector. The rise of electric vehicles (EVs) has further accelerated the demand for surface technology in the automotive industry. EVs place a premium on efficiency and durability, and surface coatings contribute to the optimization of battery components, electric drivetrains, and other critical parts. Moreover, as autonomous vehicles become more prevalent, there is an increased focus on sensor technologies, and advanced coatings are vital to ensure the reliability and longevity of sensors and cameras used in autonomous driving systems.

Surface Technology Market Regional Outlook

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

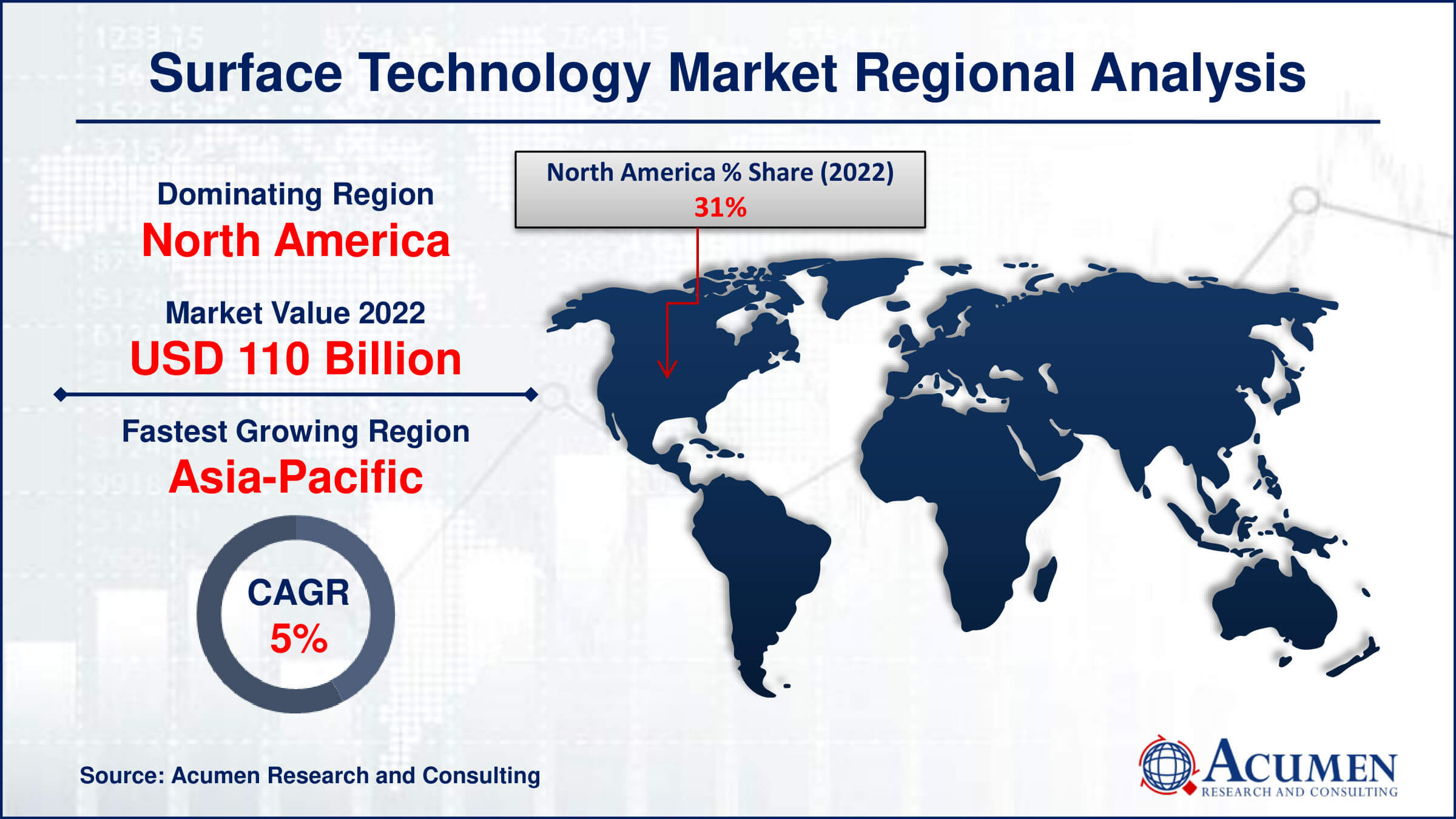

Surface Technology Market Regional Analysis

North America has asserted its dominance in the surface technology market through a combination of technological innovation, a robust industrial landscape, and a high demand for advanced materials across various sectors. The region boasts a strong presence of key industries such as aerospace, automotive, healthcare, and electronics, all of which heavily rely on cutting-edge surface technologies to enhance the performance and longevity of their products. The aerospace industry, in particular, has been a major contributor to the region's leadership, with a focus on advanced coatings for aircraft components to ensure durability, corrosion resistance, and fuel efficiency. Moreover, the North American region has been at the forefront of research and development activities in surface technology. The presence of leading research institutions, coupled with collaborations between academia and industry, has facilitated the continuous advancement of surface treatment methods and materials. This has resulted in the development and commercialization of innovative surface technologies, ranging from nanocoatings to smart coatings, which further strengthens North America's position in the global market. Additionally, the region's commitment to sustainability and environmental regulations has led to the adoption of eco-friendly surface technologies, aligning with the growing global emphasis on responsible and sustainable manufacturing practices.

Surface Technology Market Player

Some of the top surface technology market companies offered in the professional report include Bodycote, Guangdong Strong Metal Technology Co., Ltd, DOWA Thermotech Co., Ltd., FPM Heat Treating, Harterei Reese, Paulo, Surface Technology, Inc., Aalberts Surface technology, Schaeffler Group, and Linde Plc.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

July 2024

October 2018

March 2023

May 2023