July 2024

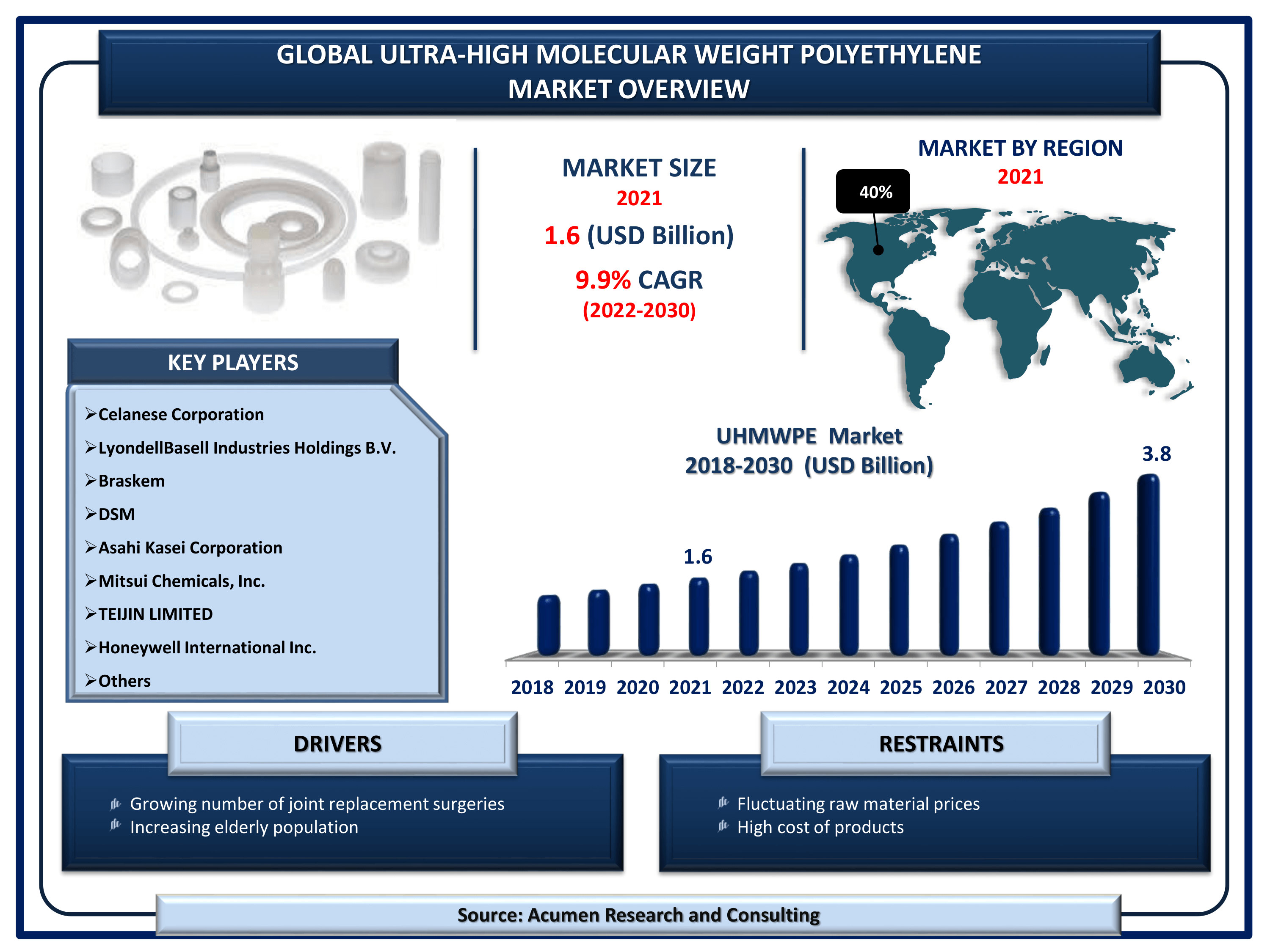

Ultra-High Molecular Weight Polyethylene Market Size accounted for USD 1.6 Billion in 2021 and is estimated to garner a market size of USD 3.8 Billion by 2030 rising at a CAGR of 9.9% from 2022 to 2030.

The Global Ultra-High Molecular Weight Polyethylene Market Size accounted for USD 1.6 Billion in 2021 and is estimated to garner a market size of USD 3.8 Billion by 2030 rising at a CAGR of 9.9% from 2022 to 2030. Increasing requirements from aerospace and defense industry is a key factor that is driving the global ultra-high molecular weight polyethylene market share. Rising use in orthopedic implants is a popular ultra-high molecular weight polyethylene market trend that is fueling the industry growth.

Ultra-High Molecular Weight Polyethylene Market Report Key Highlights

Rapid technological advancements in plastics, rising demand for durable and cost-effective raw materials, and wide applicability of UHMWPE in the medical and aerospace sector are factors expected to drive the growth of the global market. According to the School of Biomedical Engineering's report, UHMWPE is an outstanding biopolymer having high tensile strength, good biocompatibility, corrosion resistance, low water uptake, low coefficient of friction, and high abrasion resistance. These characteristics of UHMWPE are widely used and are in the major development phase in areas such as medicine and biology. As UHMWPE comprises many characteristics, it shows great advantages in the high-performance fiber market that plays a vital role in modern aviation, aerospace, and marine areas. This is due to UHMWPE having a very low surface friction coefficient, that allows bulk materials and large adhesion properties. UHMWPE fibers are strong and lightweight due to their combination of high strength and low density.

Top applications of UHMWPE in aerospace and defense include personal armor and vehicle armory for the military. For example, UHMWPE fabric for the flash flame environment when protected by flame-resistant fabric was tested, it showed high ballistic protection properties, however, needed shielding from direct flame impact. Recently developed additions to the US Military's Interceptor body armor, designed to offer arm and leg protection, are said to utilize a form of Spectra or Dyneema fabric. The number of applications with UHMWPE is rapidly increasing in personal protection (vests, inserts, and helmets), vehicle protection (land vehicles, aircraft, and ships), and high-performance apparel including cut-resistant gloves and commercial marines. Due to the unique properties of the material as a stronger and lighter solution, the market is growing for ballistic protection worldwide.

Global Ultra-High Molecular Weight Polyethylene Market Dynamics

Market Drivers

Market Restraints

Market Opportunities

Ultra-High Molecular Weight Polyethylene Market Report Coverage

| Market | Ultra-High Molecular Weight Polyethylene Market |

| Ultra-High Molecular Weight Polyethylene Market Size 2021 | USD 1.6 Billion |

| Ultra-High Molecular Weight Polyethylene Market Forecast 2030 | USD 3.8 Billion |

| Ultra-High Molecular Weight Polyethylene Market CAGR During 2022 - 2030 | 9.9% |

| Ultra-High Molecular Weight Polyethylene Market Analysis Period | 2018 - 2030 |

| Ultra-High Molecular Weight Polyethylene Market Base Year | 2021 |

| Ultra-High Molecular Weight Polyethylene Market Forecast Data | 2022 - 2030 |

| Segments Covered | By Type, By Form, By Application, By End-User Industry, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Celanese Corporation, LyondellBasell Industries Holdings B.V., Braskem, DSM, Asahi Kasei Corporation, Mitsui Chemicals, Inc. TEIJIN LIMITED, Honeywell International Inc., TSE Industries, Inc., and St. Lawrence Steel Company. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Regulation Analysis |

Ultra-High Molecular Weight Polyethylene Market Dynamics

High percentage volume of knee and hip surgeries in developed and developing countries and demand for implants with high tensile strength and long shelf life is expected to increase demand for UHMWPE products. Knee replacement and hip surgeries are becoming common across the globe, due to easy availability of advanced surgical infrastructure and favorable reimbursement policies. Worldwide, 40% of the population aged above 55 suffers from chronic pain. Out of these each year there are about 2.6 million knee replacement surgeries conducted worldwide. Countries such as China and India are spending high on the development of Filtration sector.

Factors such as fluctuating raw material prices and high cost of products are expected to hamper the growth of global market. Plastic prices are constantly changing as HDPE being the raw material for UHMWPE and high price of HDPE would increase the UHMWPE end product cost. In addition, stringent government regulations related to product approval is expected to challenge the growth of target market. Government is imposing various regulations on use of plastic in medical devices. The FDA recommends manufacturers to provide the following general technical information related to UHMWPE material for all material types and submission types to establish the type of UHMWPE in use. However, increasing investment by major players for R&D activities, focus towards development of UHMWPE from recycled products, and new product launches are factors expected to create new opportunities for players operating in the target market over the forecast period. In addition, increasing strategic agreements and public-private partnerships (PPP) is expected to support the revenue transaction of the target market.

Ultra-High Molecular Weight Polyethylene Market Segmentation

The worldwide ultra-high molecular weight polyethylene market is split based on type, form, application, end-use industry, and geography.

Ultra-High Molecular Weight Polyethylene Market By Type

Among the type segment, the powder UHMWPE segment accounted for about 48% of the global ultra-high molecular weight polyethylene UHMWPE market. On the other hand, the particle UHMWPE is anticipated to witness a substantial growth rate during the forecast period from 2022 to 2030.

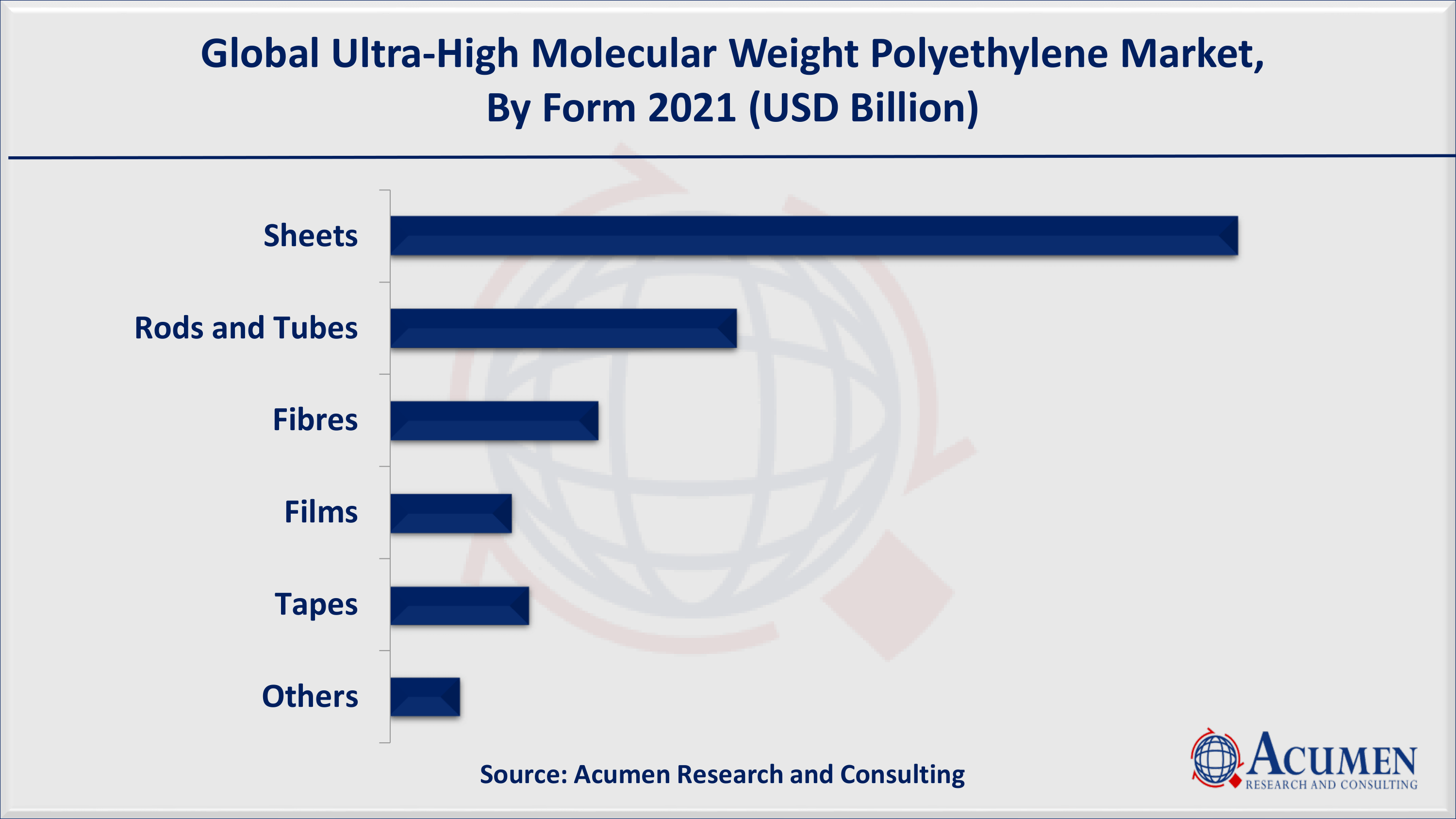

Ultra-High Molecular Weight Polyethylene Market By Form

According to our ultra-high molecular weight polyethylene industry analysis, the sheets segment is expected to have a significant market share during the forecast period. UHMWPE sheets are widely used in a variety of industries to address wear, friction, and material flow issues. This material sheet is notable for its high impact strength, excellent sliding properties, chemical resistance, and extreme wear resistance.

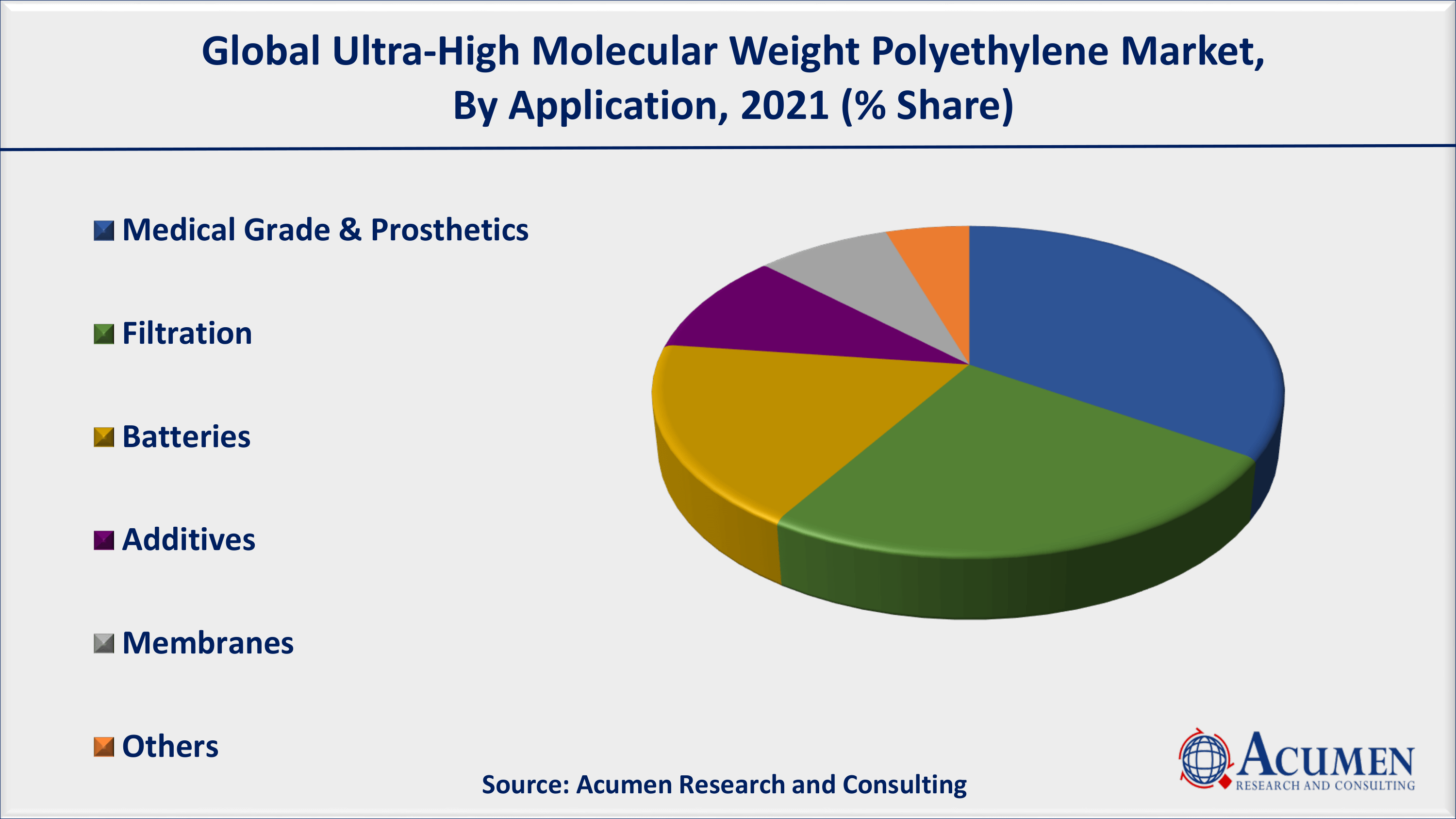

Ultra-High Molecular Weight Polyethylene Market By Application

As per our ultra-high molecular weight polyethylene market forecast, the medical grade and prosthetics application will be the most important segment UHME-PE industry. Increasing elderly population coupled with the growing demand in knee and hip replacement surgeries is fueling the medical grade and prosthetics market share. Furthermore, technological advancements in UHMWPE use as prosthetics are critical factors that are expected to positively impact the global market.

Ultra-High Molecular Weight Polyethylene Market By End-Use Industry

Among the end-user industry, healthcare and medical will account for a considerable market share. UHMWPE is a very useful material in medical device manufacturing, especially in orthopedic applications. For over 40 years UHMWPE has been material in use for medical implant applications. It's more relied upon due to its high resistance to abrasion and along with its incredibly strong and durable properties. Moreover, UHMWPE fibers are replacing PET fibers due to their small size and flexibility. The most prominent cardiac medical devices manufactured using this material includes cardiac stents, pacing devices, and structural cardiac implants. UHMWPE is popular among medical component manufacturers due to its toughness, low friction coefficient, high impact strength, etc.

Ultra-High Molecular Weight Polyethylene Market Regional Outlook

North America

Europe

Latin America

Asia-Pacific

The Middle East & Africa (MEA)

Ultra High Molecular Weight Polyethylene (UHMWPE) Market Regional Analysis

North America held the largest market share in 2021 and is expected to continue to do so in the years ahead, from 2022 to 2030. Increased military and defense budgets in the United States, as well as an increase in reported cases of joint surgeries, such as knee and hip replacements, are expected to drive UHMWPE demand in North America. Furthermore, Europe will account for a sizable share of the UHMWPE market in the coming years. Rising electric and hybrid vehicle adoption in this region is expected to drive product demand in the automotive industry. On the other hand, Asia-Pacific region is anticipated to witness the fastest growth rate in the coming years. The high growth in the region is credited to the increasing government investments and initiatives in the improvement of healthcare, aerospace and defense industries.

Ultra-High Molecular Weight Polyethylene Market Players

The global ultra-high molecular weight polyethylene companies profiled in the report include Celanese Corporation, LyondellBasell Industries Holdings B.V., Braskem, DSM, Asahi Kasei Corporation, Mitsui Chemicals, Inc. TEIJIN LIMITED, Honeywell International Inc., TSE Industries, Inc., and St. Lawrence Steel Company.

Major players are inclining towards emerging economies in order to track the untapped market. These are some factors expected to augment the growth of the target market.

Players’ inclination towards increasing the business through strategic mergers and agreements is expected to impact the growth of the target market.

In 2021, Koninklijke DSM N.V., a global health product service provider collaborated with Saudi Basic Industries Corporation with the focus to create new recycled based “Dyneema”. The partnership is expected to create new opportunities for the company to enhance its product portfolio in UHMWPE made from recycled products.

In 2018, Honeywell, a global conglomerate company announced that Safariland Group, a global manufacturer of personal products is utilizing the companies made UHMWPE product “Spectra Shield” in the design of the ballistic handheld shields. The resulting shields can be up to 20% lighter and are introducing the new design in its new X Series line of lightweight ballistic shields, sold under the PROTECH Tactical brand.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

July 2024

October 2024

June 2023

July 2023