December 2023

The Global Wood Coating Resins Market Size accounted for USD 9.8 Billion in 2023 and is estimated to achieve a market size of USD 14.2 Billion by 2032 growing at a CAGR of 4.3% from 2024 to 2032.

Wood coating resins are specialized compositions that protect and improve the appearance of wood surfaces. These resins form a strong covering that protects the wood from environmental elements like moisture, UV light, and abrasion. Acrylic, polyurethane, and epoxy resins are common varieties, each with their own set of advantages such as flexibility, hardness, and durability. Wood coating resins are commonly used in furniture, flooring, cabinets, and architectural wood applications to give long-term protection. They also enhance the aesthetic appeal by adding gloss, color, or a natural finish, all while maintaining sustainability with low-VOC and eco-friendly alternatives.

|

Market |

Wood Coating Resins Market |

|

Wood Coating Resins Market Size 2023 |

USD 9.8 Billion |

|

Wood Coating Resins Market Forecast 2032 |

USD 14.2 Billion |

|

Wood Coating Resins Market CAGR During 2024 - 2032 |

4.3% |

|

Wood Coating Resins Market Analysis Period |

2020 - 2032 |

|

Wood Coating Resins Market Base Year |

2023 |

|

Wood Coating Resins Market Forecast Data |

2024 - 2032 |

|

Segments Covered |

By Type, By Product Type, By Application, and By Geography |

|

Regional Scope |

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Nuplex Industries Limited, Helios Group, Synthopol Chemie Dr. rer. pol. Koch GmbH & Co. KG, Sirca Spa, Dynea AS, Polynt Spa, IVM Group, Allnex S.à.r.l., Arkema S.A., and Koninklijke DSM N.V |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

The wood coating resins market is expected to grow during the forecast period, driven by the increasing demand for environmentally friendly, durable resins that offer enhanced performance and aesthetics, as well as a rise in the need for solvent-free and water-based coatings. For instance, as industries prioritize environmentally friendly solutions, there is a growing demand for sustainable alternatives such as green resins and bio-carbon composites. To improve safety and reduce carbon footprints, the technology owner created a line of green resins containing up to 85% bio-carbon and low VOC content. These green resins, which are made from renewable feedstocks, are less hazardous and require only one GHS symbol or none, according to RSC Publishing.

Furthermore, the emergence end-use industries are expected to drive market expansion. The American Coatings Association defines industrial wood coatings as covering a wide range of industry categories such as furniture, kitchen cabinets, structural materials, and ornamental uses. However, several factors may impede growth, including the higher cost of water-based coatings compared to solvent-based alternatives, the continued use of solvent-based coatings that do not comply with VOC regulations, and the preference of furniture manufacturers for particle boards and other metal materials over wood.

The rising need for wood in the near future is predicted to propel the wood coating resins business to prominence in the coming years. For example, the Food and Agriculture Organization projects that global roundwood production would increase by 4-8% between 2022 and 2030, indicating moderate growth in the near term. By 2050, roundwood production is expected to increase by 6-32%, with volumes ranging from 240 million m³ to 1,200 million m³, depending on the scenario. This rising production is expected to drive increased demand for wood coating resins, as the need for protective and decorative coatings grows alongside the expanding wood products market.

The worldwide market for wood coating resins is split based on resin type, product type, application, and geography.

According to the wood coating resins industry analysis, acrylic resin is the most popular type in the market because of its superior features such as durability, UV resistance, and transparency. It gives a smooth finish and improves the visual appeal of wood surfaces while protecting them from environmental influences such as moisture and sunshine. Furthermore, acrylic-based coatings are commonly selected because of their low VOC emissions, which align with the growing desire for environmentally acceptable alternatives. Their versatility in applications like as furniture, cabinetry, and ornamental wood goods strengthens their market leadership.

According to the wood coating resins market forecast, waterborne wood coating resins is expected to dominate the market because they are environmentally friendly, contain low volatile organic compound (VOC) content, and are sustainable product. These resins are widely used in both residential and commercial applications due to their outstanding durability and performance. Radiation cure resins are gaining popularity due to their short cure time and low environmental effect, making them excellent for high-throughput applications. High-solid resins are used because they may give a thicker coating using fewer solvents, lowering emissions and enhancing efficiency. Solvent-borne resins are still commonly used due to their high adherence and outstanding performance in severe environments, but they are rapidly being replaced by more environmentally friendly alternatives.

According to the wood coating resins market forecast, the furniture segment leads market due to the strong demand for attractive and long-lasting finishes in residential, commercial, and industrial furniture. Wood treatments improve the aesthetics and durability of furniture by protecting it from scratches, stains, and environmental damage. Rising home décor trends, combined with increased expenditure on high-end furniture, are driving demand for sophisticated wood coating resins. Furthermore, advances in resin technology, such as eco-friendly and quick-drying coatings, have increased their use in the furniture business.

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

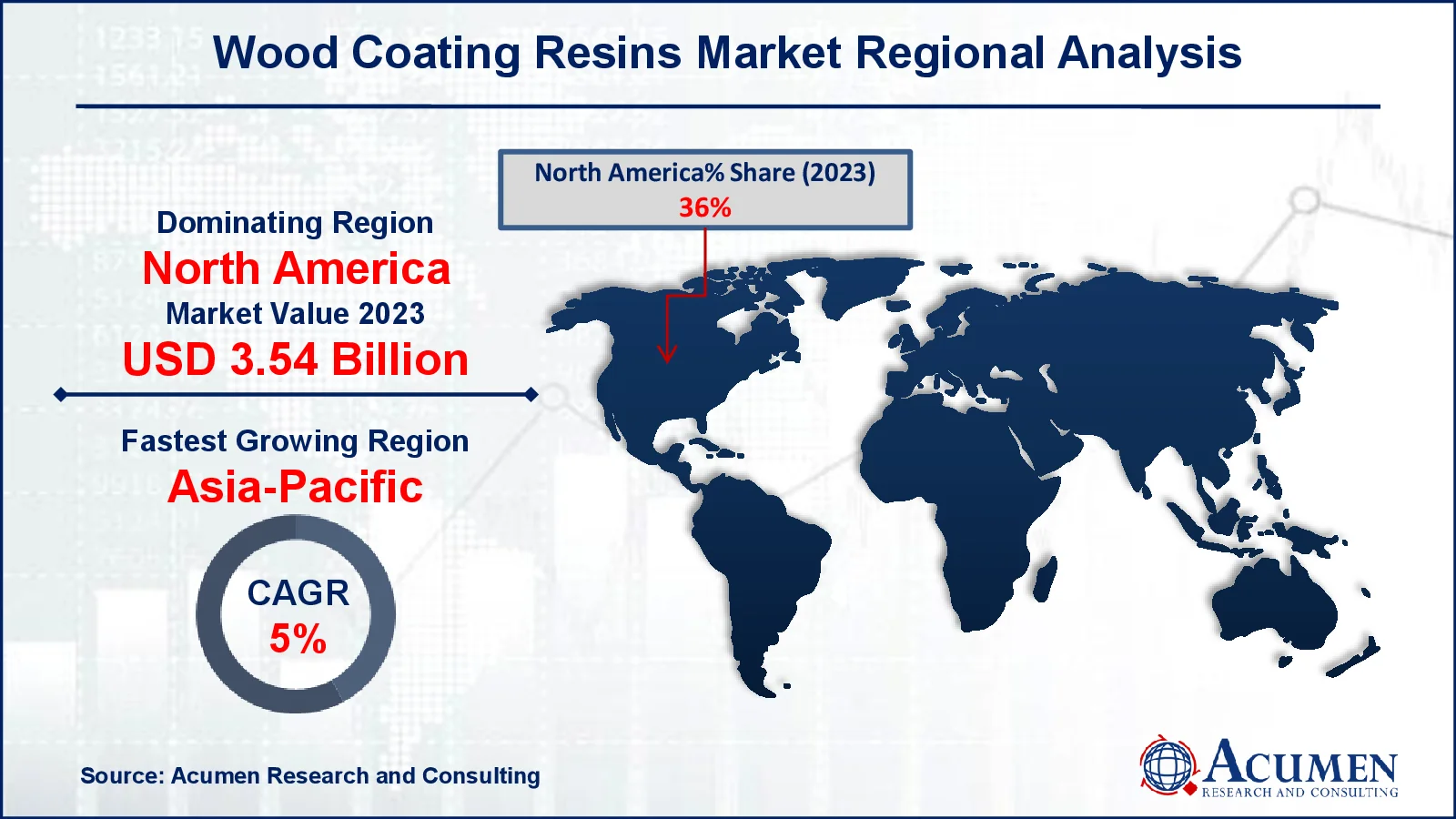

For several reasons, North America dominates in the wood coating resins market due to a thriving construction and furniture industry. In December 2021, Empire Office, Inc. announced that it has entered into an agreement to buy DeKalb Office Environments, Inc., establishing its local presence in Atlanta and Birmingham. This partnership between furniture producers strengthens the furniture market presence in the American region, which in turn enhances the growth of the wood coating resins market. Increased demand for high-quality, durable, and eco-friendly wood coatings is driving the adoption of advanced resin technologies in residential, commercial, and industrial applications.

Asia-Pacific is fastest-growing market for wood coating resins, followed by North America, Latin America, and MEA. Rising disposable income, a growing middle-class population, and demand from diverse end-use industries are expected to drive the wood furniture industry, and therefore the wood coating resins market. For instance, as per Invest India, over the coming years, the domestic furniture market is anticipated to grow at a faster pace than the global average, increasing from $17 billion in FY 2021 to $37 billion by 2026. The rising popularity of furniture that blends traditional handicraft designs with modern design is fostering a unique segment that retains the Indian essence in the domestic furniture market. This growth is expected to boost the demand for wood coating resins, driven by the need for durable and aesthetically pleasing finishes.

Some of the top wood coating resins companies offered in our report includes Nuplex Industries Limited, Helios Group, Synthopol Chemie Dr. rer. pol. Koch GmbH & Co. KG, Sirca Spa, Dynea AS, Polynt Spa, IVM Group, Allnex S.à.r.l., Arkema S.A., and Koninklijke DSM N.V.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

December 2023

June 2025

December 2024

March 2023