The Global Aluminum Extrusion Market Size accounted for USD 87.4 Billion in 2024 and is estimated to achieve a market size of USD 175.8 Billion by 2033 growing at a CAGR of 8.2% from 2025 to 2033

The Global Aluminum Extrusion Market Size accounted for USD 87.4 Billion in 2024 and is estimated to achieve a market size of USD 175.8 Billion by 2033 growing at a CAGR of 8.2% from 2025 to 2033.

Aluminum Extrusion Market Highlights

Aluminum is a lightweight, robust, flexible, corrosion-free, and infinitely recyclable metal. Aluminum extrusion is a procedure for transforming aluminum alloys into products with a distinct cross-sectional profile that are employed in a number of applications. Aluminum's mixability makes it easy to machine and cast, yet its density and consistency are one-third that of steel, thus the final products are strong and stable, especially when alloyed with other metals. Aluminum extrusion relies heavily on heat. Temperature monitoring from start to end is critical to ensuring that aluminum alloy parameters such as tensile and rating strengths are satisfied, as well as the component's finish. The aluminum alloy is still solid, if murky. Aluminum looks the same when heated as it does when cold. It doesn't shine.

Aluminum is a lightweight, robust, flexible, corrosion-free, and infinitely recyclable metal. Aluminum extrusion is a procedure for transforming aluminum alloys into products with a distinct cross-sectional profile that are employed in a number of applications. Aluminum's mixability makes it easy to machine and cast, yet its density and consistency are one-third that of steel, thus the final products are strong and stable, especially when alloyed with other metals. Aluminum extrusion relies heavily on heat. Temperature monitoring from start to end is critical to ensuring that aluminum alloy parameters such as tensile and rating strengths are satisfied, as well as the component's finish. The aluminum alloy is still solid, if murky. Aluminum looks the same when heated as it does when cold. It doesn't shine.

Global Aluminum Extrusion Market Dynamics

Market Drivers

Market Restraints

Market Opportunities

Aluminum Extrusion Market Report Coverage

|

Market |

Threadlocker Market |

|

Aluminum Extrusion Market Size 2024 |

USD 87.4 Billion |

|

Aluminum Extrusion Market Forecast 2033 |

USD 175.8 Billion |

|

Aluminum Extrusion Market CAGR During 2025 - 2033 |

8.2% |

|

Aluminum Extrusion Market Analysis Period |

2021 - 2033 |

|

Aluminum Extrusion Market Base Year |

2024 |

|

Aluminum Extrusion Market Forecast Data |

2025 - 2033 |

|

Segments Covered |

By Type, By Product, By Application, and By Geography |

|

Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Kaiser Aluminum, Tajik Aluminium Company, Gulf Extrusions Co. LLC, Bahrain Aluminum Extrusion Company, Hindalco Industries Ltd., QALEX, Arconic Corp., Norsk Hydro ASA, Alupco, and Constellium N.V. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Aluminum Extrusion Market Insights

The global market for aluminum extrusion products is driven by its prominent presence as steel substitutes for autos and transportation. The extrusion is quite simple. Use a huge hydraulic press to drag a hot aluminum ticket through a die. Approximately 40% of all extrusions are colored, anodized, or partially powdered. Almost every extrusion is created in some fashion, whether by the extruder, the consumer, or a third party.

Aluminum extrusion materials are recyclable and resistant to oxidation, ensuring the endurance of the overall system in which they are utilized. However, during the projection period, a lack of awareness of such items will limit market expansion. Aluminum extrusions' low manufacturing costs, combined with the simplicity with which they may be recycled, have expanded their industrial, transportation, domestic, and daily applications.

Direct extrusion is the most prevalent of all extrusion methods. A metal billet is pushed in the same direction through the die opening as the pressure applied to it. The main benefit of this technology is its high productivity, as the extruder's whole duration is often restricted by the width of the metal billet. The disadvantage of the system is that there is friction at the billet/container interface.

Aluminum extrusion has a wide range of applications, including international space station modules. Aluminum's advantages, including its unique strength and ductility mix, conductivity, non-magnetic characteristics, and ability to be recycled repeatedly without losing integrity, enable such a wide range of applications. In India, aluminum extruders have a capacity of around 550 000 tons per year. This capacity is split across approximately 150 presses ranging from 360 T to 9000 T.

Aluminum Extrusion Market Segmentation

Aluminum Extrusion Market Segmentation

The worldwide market for aluminum extrusion is split based on type, product, application, and geography.

Aluminum Extrusion Market By Type

According to aluminum extrusion industry analysis, mill-finished aluminum extrusions are predicted to dominate the industry due to their low cost, adaptability, and wide range of applications, including construction, automotive, and electronics. This kind requires minimal processing, making it an appealing alternative for producers searching for raw or semi-finished materials that can be further tailored to meet specific specifications. Furthermore, its excellent recyclability and durability make it a popular choice for businesses that value sustainability and efficiency.

Aluminum Extrusion Market By Product

According to aluminum extrusion industry analysis, shapes products take the lead because of their versatility, structural strength, and widespread application in industries such as construction, automotive, and aerospace. These extruded profiles, which include channels, angles, and complex cross-sections, provide great precision and design freedom, allowing manufacturers to produce lightweight but durable components. Their flexibility to be modified for individual applications, combined with superior thermal and electrical conductivity, increases demand.

Aluminum Extrusion Market By Application

According to aluminum extrusion market forecast, construction and building industry represents the world's largest aluminum extrusion market. Aluminum extrusions are commonly utilized in windows, doors, curtain walls, and frame systems, resulting in energy-efficient and modern architectural designs. Growing urbanization, infrastructural development, and rising demand for sustainable building materials all contribute to the increase of aluminum extrusions in the construction industry. According to the India Brand Equity Foundation (IBEF), foreign investors invest approximately US$ 3.1 billion annually in Indian real estate, with a 37% YoY rise in the first half of 2024. This industry is expected to grow, with around 61% of aluminum in buildings recycled each year.

Aluminum Extrusion Market Regional Outlook

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

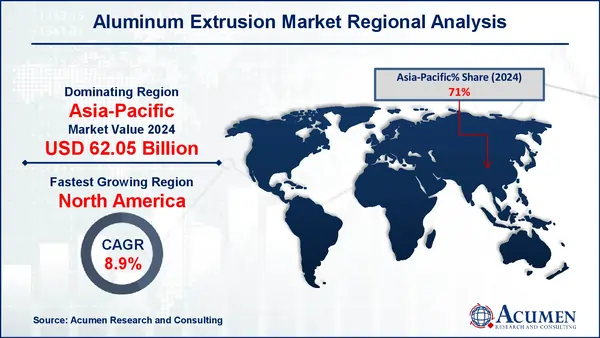

Aluminum Extrusion Market Regional Analysis

Aluminum Extrusion Market Regional Analysis

In terms of regional segments, Asia-Pacific leads the worldwide aluminum extrusion market, led by large economies such as China and India, which are experiencing a boom in demand. The Indian government has invested heavily in infrastructure, including trains, electric vehicles, metro systems, smart cities, solar energy, and defense projects. According to the IBEF, the government budgeted Rs. 2.76 lakh crore (US$ 33.4 billion) to the Ministry of Roads in 2024-25, while the Railways received Rs. 2.55 lakh crore (US$ 30.72 billion), representing a 5.8% increase over the previous year. Furthermore, the solar power grid received Rs. 8,500 crores (US$ 1.02 billion). These developments increase aluminum consumption, which supports market growth in India. However, while these initiatives generate potential, they also bring hurdles for upgrading aluminum extrusion operations in India and around the world.

North America's aluminum extrusion industry is likewise rapidly expanding, owing to advances in production technology and a growing emphasis on lightweight, sustainable materials. A notable example is the Ford F-150, the best-selling truck in the United States, which now uses high-strength aluminum in its body and frame. This transition improves fuel economy and performance by dramatically lowering weight. The rising use of lightweight materials in the automobile industry is a major driver of aluminum extrusion growth in North America.

Aluminum Extrusion Market Players

Some of the top aluminum extrusion companies offered in our report include Kaiser Aluminum, Tajik Aluminium Company, Gulf Extrusions Co. LLC, Bahrain Aluminum Extrusion Company, Hindalco Industries Ltd., QALEX, Arconic Corp., Norsk Hydro ASA, Alupco, and Constellium N.V.

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@acumenresearchandconsulting.com