March 2024

The Cold Rolled Steel Coil Market, valued at USD 151.8 Million in 2024, is projected to reach USD 200.9 Million by 2033, growing at a 3.2% CAGR from 2025 to 2033.

The Global Cold Rolled Steel Coil Market Size accounted for USD 151.8 Million in 2024 and is estimated to achieve a market size of USD 200.9 Million by 2033 growing at a CAGR of 3.2% from 2025 to 2033.

Cold rolled steel coils are steel products that pass through a series of cold reduction mills, where the material is cooled (at room temperature), annealed, and/or temper rolled. This process increases the steel's strength and hardness while providing a smooth, polished finish. The cold rolling process begins with hot-rolled steel, which is then processed in cold reduction mills to remove scale and rust. The end result is a steel coil that is thinner, more accurate, and of superior quality. These coils are very desirable in industries that require precise dimensions and good surface quality, such as automotive, appliance, furniture, and construction.

|

Market |

Cold Rolled Steel Coil Market |

|

Cold Rolled Steel Coil Market Size 2024 |

USD 151.8 Million |

|

Cold Rolled Steel Coil Market Forecast 2033 |

USD 200.9 Million |

|

Cold Rolled Steel Coil Market CAGR During 2025 - 2033 |

3.2% |

|

Cold Rolled Steel Coil Market Analysis Period |

2021 - 2033 |

|

Cold Rolled Steel Coil Market Base Year |

2024 |

|

Cold Rolled Steel Coil Market Forecast Data |

2025 - 2033 |

|

Segments Covered |

By Material Composition, By Application, By End-Use Industry, and By Geography |

|

Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

AK Steel Holding Corporation, ArcelorMittal, Baosteel Group Corporation, China Steel Corporation, Hyundai Steel Company, JFE Steel Corporation, Nippon Steel Corporation, Nucor Corporation, POSCO, Severstal, SSAB AB, Tata Steel, Thyssenkrupp AG, United States Steel Corporation, and Voestalpine AG. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

There are various factors that affect the cold rolled steel coil sector. One of the primary factors is rising demand from the automotive industry, which requires high-quality steel for the manufacture of a variety of components. The rise of the building sector, particularly in emerging markets, is increasing demand for cold rolled steel coils with higher strength and surface polish, which are ideal for structural applications. Furthermore, as infrastructure development and industrial activity grow, so does urbanization and industrialization, both of which contribute to market expansion. Manufacturing process advances improve the quality and efficiency of cold rolled steel coils, making them more appealing to a wider range of end customers.

Despite its hopeful outlook, the cold rolled steel coil market faces various challenges. Fluctuating raw material prices can have an impact on manufacturing costs, creating uncertainty for businesses and lowering profit margins. The market is also facing stiff competition from alternative materials such as aluminum, which is lighter and typically preferred in specialized applications such as vehicle manufacturing. Furthermore, severe environmental rules limit industrial capacity and need large investments in compliance and sustainability measures, putting a pressure on resources and raising operational costs for enterprises.

In contrast, the cold-rolled steel coil market has a plethora of opportunities. The increased usage of renewable energy infrastructure, such as wind turbines and solar panel installations, creates new opportunities for market participants. Increased spending in R&D initiatives are designed to improve product quality and provide distinctive responses to changing industry demands. Furthermore, the growing need for lightweight and high-strength materials in a range of industries, particularly automotive and aerospace, presents a substantial opportunity for the usage of advanced cold rolled steel coils, driving market growth and diversification.

Cold Rolled Steel Coil Market Segmentation

Cold Rolled Steel Coil Market SegmentationThe worldwide market for cold rolled steel coil is split based on material composition, application, end-use industry, and geography.

According to the cold rolled steel coil industry analysis, carbon steel dominates the cold rolled steel coils market because of its adaptability, cost-effectiveness, and superior mechanical qualities. It is widely utilized in a variety of industries, including automotive, construction, and manufacturing, due to its strength and low cost. Carbon steel is the chosen material in the cold rolled steel coil market due to its ability to suit a wide range of application needs, as well as its availability and ease of processing.

Automobile body panels dominate the cold rolled steel coils industry. The car industry requires high-quality steel for body panels because of its strength, durability, and outstanding surface polish. Cold rolled steel coils are popular because of their precise dimensions and excellent mechanical qualities, which are necessary for producing lightweight and fuel-efficient vehicles. The developing automotive sector, which is driven by increased vehicle production and the demand for innovative materials, plays a vital role in automotive body panels' supremacy in the cold rolled steel coil market.

As per the cold rolled steel coil market forecast, the construction industry is predicted to dominate the market from 2024 to 2032. Cold rolled steel coils are in high demand in the construction industry due to their strength, durability, and structural adaptability. These coils are frequently utilized in building frameworks, roofing, and cladding due to their ability to tolerate changing weather conditions while maintaining long-term structural integrity. The construction sector's consistent growth, especially in developing nations, continues to fuel the market's expansion, making it a key end-use industry for cold rolled steel coils.

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Cold Rolled Steel Coil Market Regional Analysis

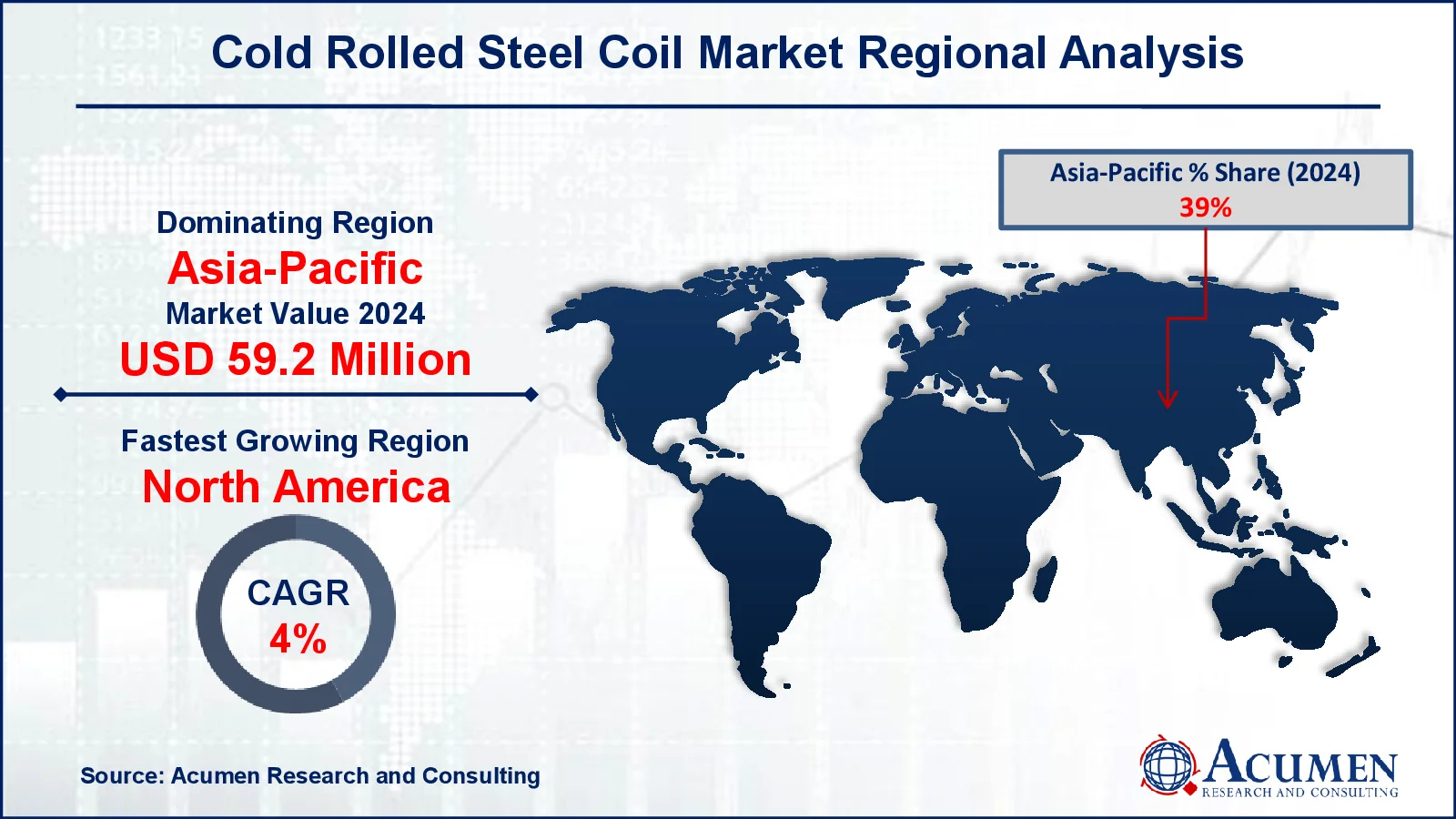

Cold Rolled Steel Coil Market Regional AnalysisIn the cold rolled steel coil market forecast period, the Asia-Pacific (APAC) region now leads the industry. Strong industrialization, expanding urbanization, and huge infrastructure investments in countries such as China, India, Japan, and South Korea have contributed to this domination. China, in particular, plays a crucial role due to its immense industrial capacity and massive growth initiatives. The automobile industry in APAC also contributes significantly to the need for cold rolled steel coils, which is being driven by the region's growing middle class and rising consumer buying power.

Furthermore, APAC benefits from the existence of major market players and technological advancements in steel production, which boost product quality and efficiency. Government initiatives to support infrastructure development drive up regional demand for cold rolled steel coils. These characteristics, together, position APAC as the primary hub for cold rolled steel coils, with continued industrial expansion and infrastructure projects driving market growth.

North America and Europe are closely following, relying on contemporary manufacturing capabilities and strong quality standards to maintain a sizable global market share. These facilities focus on niche markets such as automotive and aerospace, where cold rolled steel coils are essential for their superior mechanical properties and surface finishes.

Some of the top cold rolled steel coil companies offered in our report include AK Steel Holding Corporation, ArcelorMittal, Baosteel Group Corporation, China Steel Corporation, Hyundai Steel Company, JFE Steel Corporation, Nippon Steel Corporation, Nucor Corporation, POSCO, Severstal, SSAB AB, Tata Steel, Thyssenkrupp AG, United States Steel Corporation, and Voestalpine AG.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

March 2024

April 2020

March 2023

February 2023