February 2018

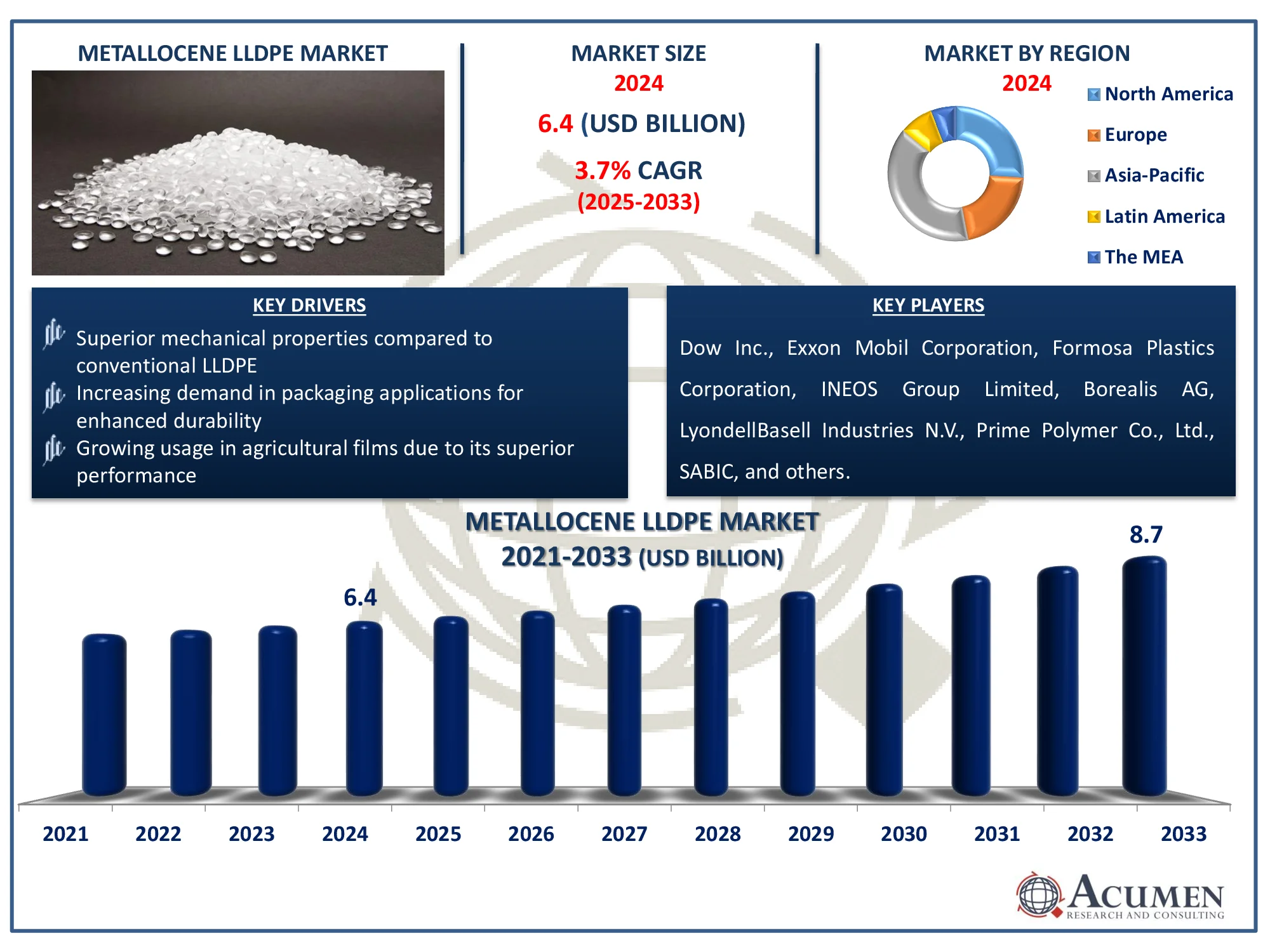

The Global Metallocene LLDPE Market Size accounted for USD 6.4 Billion in 2024 and is estimated to achieve a market size of USD 8.7 Billion by 2033 growing at a CAGR of 3.7% from 2025 to 2033.

The Global Metallocene LLDPE Market Size accounted for USD 6.4 Billion in 2024 and is estimated to achieve a market size of USD 8.7 Billion by 2033 growing at a CAGR of 3.7% from 2025 to 2033.

Metallocene linear low-density polyethylene (mLLDPE) is a kind of polyethylene made with metallocene catalysts. These catalysts are more exact than typical catalysts, giving you greater control over the polymer's molecular structure. As a result, mLLDPE offers superior qualities than traditional LLDPE, such as increased toughness, clarity, and tensile strength. The metallocene technique produces polymers with uniform molecular weight distribution and precise comonomer insertion, resulting in a higher performance material that is especially valuable in applications requiring exceptional mechanical qualities and optical clarity.

Metallocene linear low-density polyethylene (mLLDPE) is a kind of polyethylene made with metallocene catalysts. These catalysts are more exact than typical catalysts, giving you greater control over the polymer's molecular structure. As a result, mLLDPE offers superior qualities than traditional LLDPE, such as increased toughness, clarity, and tensile strength. The metallocene technique produces polymers with uniform molecular weight distribution and precise comonomer insertion, resulting in a higher performance material that is especially valuable in applications requiring exceptional mechanical qualities and optical clarity.

mLLDPE is frequently utilized in the packaging industry due to its superior sealing qualities, puncture resistance, and flexibility. It is widely used in the manufacture of films for food packaging, stretch wrap, and heavy-duty sacks. Furthermore, its improved mechanical qualities make it appropriate for use in industrial packaging, agricultural films, and consumer products. Manufacturers benefit from the material's better processability and uniformity because it enables more efficient production processes and reduces material waste. Overall, mLLDPE's unique qualities and numerous applications make it a popular choice in industries that require high-performance polyethylene.

|

Market |

Metallocene LLDPE Market |

|

Metallocene LLDPE Market Size 2024 |

USD 6.4 Billion |

|

Metallocene LLDPE Market Forecast 2033 |

USD 8.7 Billion |

|

Metallocene LLDPE Market CAGR During 2025 - 2033 |

3.7% |

|

Metallocene LLDPE Market Analysis Period |

2021 - 2033 |

|

Metallocene LLDPE Market Base Year |

2024 |

|

Metallocene LLDPE Market Forecast Data |

2025 - 2033 |

|

Segments Covered |

By Type, By Application, By End-Use Industry, and By Geography |

|

Regional Scope |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

|

Key Companies Profiled |

Dow Inc., Exxon Mobil Corporation, Formosa Plastics Corporation, INEOS Group Limited, Borealis AG, LyondellBasell Industries N.V., Prime Polymer Co., Ltd., SABIC, Chevron Phillips Chemical Company, and Total Petrochemicals USA. |

|

Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

The metallocene linear low-density polyethylene market is influenced by a number of main factors. One of the key motivations is mLLDPE's higher performance characteristics when compared to standard LLDPE. Metallocene catalysts provide greater control over the polymer structure, resulting in improved mechanical qualities such as increased tensile strength, impact resistance, and clarity. These characteristics make mLLDPE particularly appealing for use in high-quality packaging films, agricultural films, and industrial films where performance and durability are essential. The increased demand for high-performance packaging materials from the food and beverage, healthcare, and consumer goods industries is driving metallocene linear low-density polyethylene market expansion.

Despite its benefits, the mLLDPE market has various constraints that may limit its growth. Metallocene catalysts have greater production costs than typical catalysts, which presents a considerable hurdle. This pricing gap may hinder the adoption of mLLDPE, especially among small and medium-sized businesses that are vulnerable to price swings. Furthermore, the scarcity of metallocene catalysts might cause supply chain disruptions, compromising the regular manufacture of mLLDPE. Fluctuations in raw material costs, notably ethylene, add to market instability, affecting the total cost structure and profitability of mLLDPE makers.

Technological developments and new applications have created numerous opportunities in the mLLDPE market. The development of new and more efficient metallocene catalysts has the potential to significantly lower manufacturing costs and improve the characteristics of mLLDPE, making it more competitive with regular LLDPE. The increased emphasis on sustainability and environmental responsibility creates new opportunities for mLLDPE, since its superior mechanical qualities enable the manufacturing of thinner, stronger films, decreasing material usage and waste. Furthermore, expanding into new areas, where industrialization and urbanization are quickly increasing, offers tremendous growth opportunities. These regions are experiencing an increase in demand for high-quality packaging and construction materials, creating an atmosphere conducive to the use of mLLDPE.

Metallocene LLDPE Market Segmentation

Metallocene LLDPE Market SegmentationThe worldwide market for metallocene LLDPE is split based on type, application, end-use industry, and geography.

According to metallocene LLDPE industry analysis, C8 mLLDPE (octene-based metallocene LLDPE) has dominated the market due to superior qualities over other varieties. C8 mLLDPE has improved toughness, puncture resistance, and clarity, making it perfect for high-performance applications such premium packaging films and industrial films. Its ability to make stronger and thinner films without sacrificing strength or durability has made it the top choice for producers looking for high-quality, efficient materials. C8 mLLDPE has been widely used due to its adaptability and high mechanical properties, making it the dominant type in the metallocene LLDPE market.

As per the metallocene LLDPE market forecast, film applications, namely packaging films, would dominate due to its widespread use in food packaging, consumer goods, and industrial applications. This dominance stems from mLLDPE's outstanding qualities, which include excellent strength, puncture resistance, and clarity, making it perfect for flexible packaging applications. Agricultural films also serve an important role, benefiting from mLLDPE's durability and barrier characteristics. While other applications such as rotational molding, injection molding, and pipe coatings contribute to the market, film applications stand out due to their widespread use across several industries, creating significant demand and market share in the mLLDPE segment.

The food and beverage sectors, holds a substantial share of the mLLDPE (metallocene linear low-density polyethylene) market. The exceptional qualities of mLLDPE, such as high strength, flexibility, and barrier performance, are ideal for the severe needs of food packaging and preservation. The consumer products industry also plays an important role, since it uses mLLDPE in a variety of packaging applications due to its exceptional clarity and impact resistance. While other industries, such as healthcare, agricultural, and industrial applications, benefit from the adaptability and durability of mLLDPE, the packaging industry remains the major user, creating significant demand and market growth for mLLDPE globally.

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

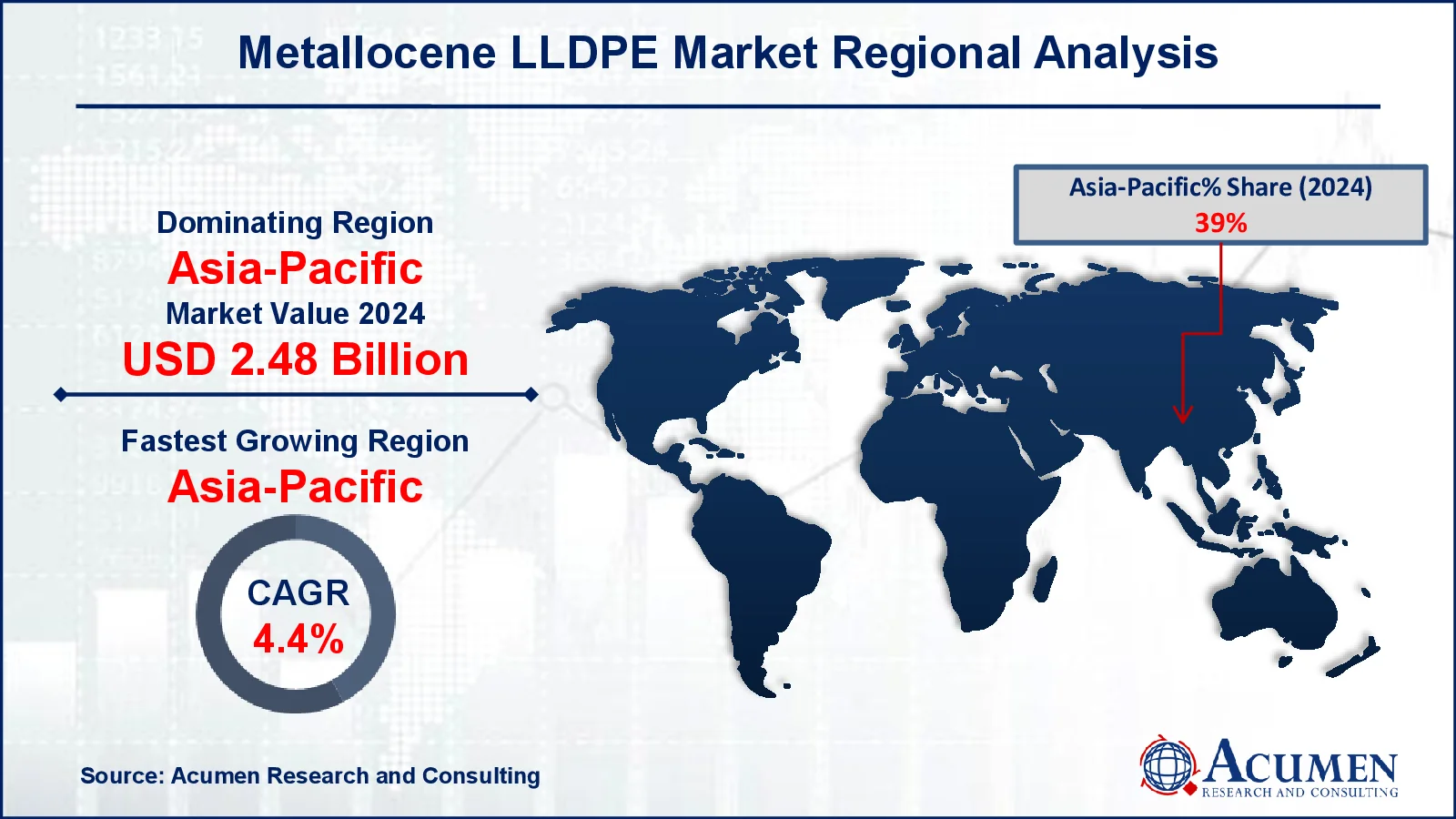

Metallocene LLDPE Market Regional Analysis

Metallocene LLDPE Market Regional AnalysisThe regional study of the metallocene linear low-density polyethylene (mLLDPE) market reveals various demand patterns in key worldwide areas. Rapid industrialization and urbanization in Asia-Pacific are driving increasing demand for mLLDPE in the packaging, construction, and automotive industries, which is backed by rising consumer markets and infrastructure development. The region also benefits from increased agricultural activity, which raises demand for mLLDPE in agricultural films and other uses.

North America and Europe are major markets, driven by tight packaging requirements and a significant emphasis on environmentally friendly packaging solutions. These regions value mLLDPE for its better performance in food packaging and consumer goods, indicating strong growth in these industries.

Latin America, the Middle East, and Africa are seeing an increase in mLLDPE use as industrial sectors and infrastructural projects expand. These regions use mLLDPE for packaging, building, and industrial uses, which are aided by economic expansion and increased urbanization. Overall, while mature markets in North America and Europe lead in terms of technological advancements and stringent regulatory environments that encourage mLLDPE adoption, Asia-Pacific and emerging regions provide significant growth opportunities in metallocene linear low-density polyethylene (mLLDPE) market.

Some of the top metallocene LLDPE companies offered in our report include Dow Inc., Exxon Mobil Corporation, Formosa Plastics Corporation, INEOS Group Limited, Borealis AG, LyondellBasell Industries N.V., Prime Polymer Co., Ltd., SABIC, Chevron Phillips Chemical Company, and Total Petrochemicals USA.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

February 2018

May 2023

May 2025

July 2024