May 2018

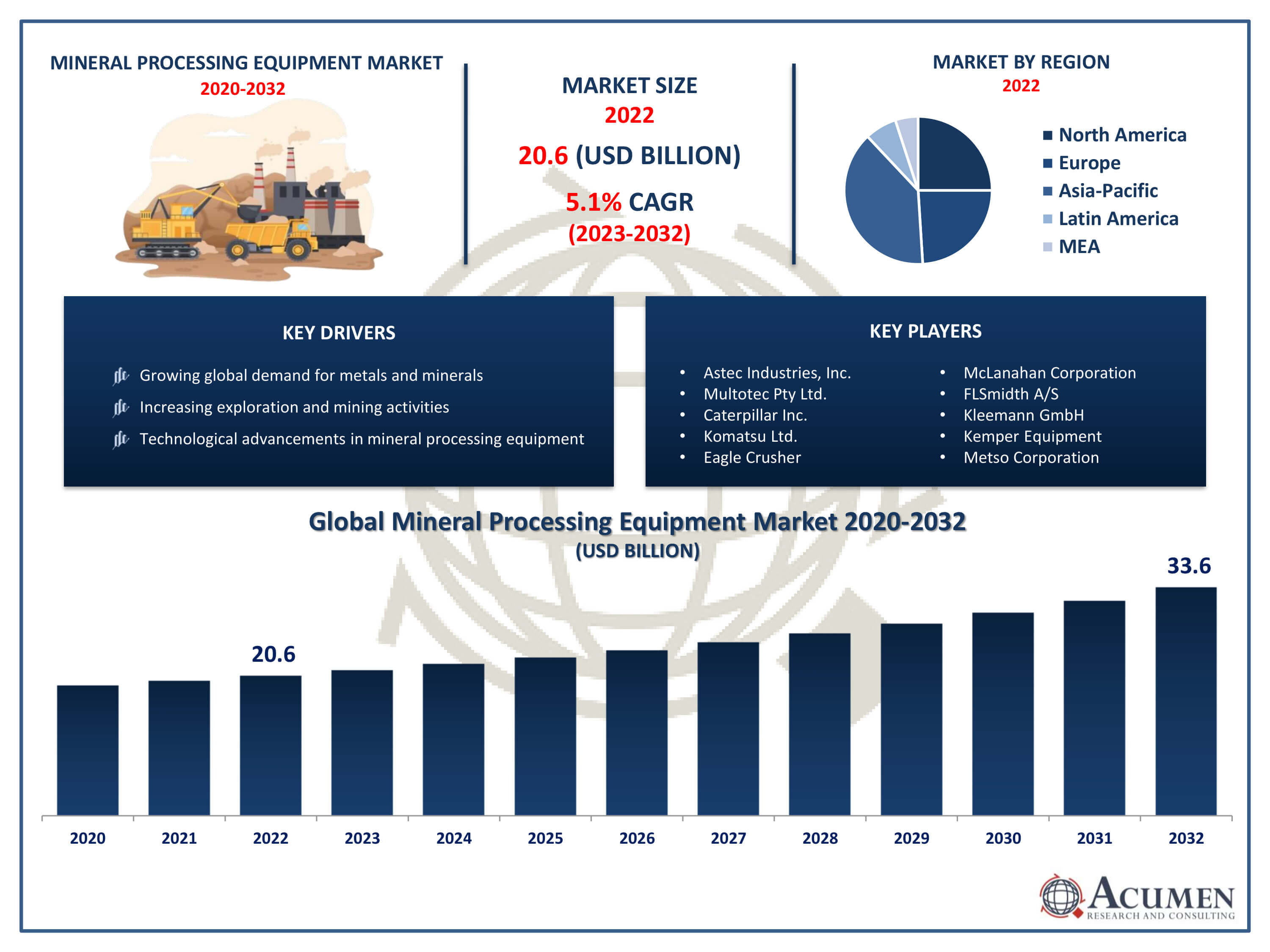

Mineral Processing Equipment Market Size accounted for USD 20.6 Billion in 2022 and is projected to achieve a market size of USD 33.6 Billion by 2032 growing at a CAGR of 5.1% from 2023 to 2032.

The Global Mineral Processing Equipment Market Size accounted for USD 20.6 Billion in 2022 and is projected to achieve a market size of USD 33.6 Billion by 2032 growing at a CAGR of 5.1% from 2023 to 2032.

Mineral Processing Equipment Market Highlights

Mineral processing equipment refers to machinery and tools used for the mechanical and physical separation, classification, and concentration of minerals from their ores. The primary goal of mineral processing is to extract valuable minerals or metals from the raw ore and prepare them for further use or refining. This process involves various unit operations, such as crushing, grinding, screening, and gravity separation, among others. Mineral processing equipment plays a crucial role in optimizing the efficiency of these operations, ensuring the economic viability of mining projects, and meeting the increasing global demand for minerals.

The market for mineral processing equipment has experienced substantial growth in recent years, driven by several factors. Firstly, the rising demand for metals and minerals across various industries, including construction, energy, and manufacturing, has stimulated increased exploration and mining activities globally. This, in turn, has led to a growing need for efficient and advanced mineral processing equipment to extract and process these resources. Additionally, technological advancements in mining equipment, such as automation and digitalization, have improved operational efficiency, reduced environmental impact, and enhanced safety in mining operations. As the mining industry continues to evolve and adopt innovative technologies, the market for mineral processing equipment is expected to witness sustained growth in the coming years.

Global Mineral Processing Equipment Market Trends

Market Drivers

Market Restraints

Market Opportunities

Mineral Processing Equipment Market Report Coverage

| Market | Mineral Processing Equipment Market |

| Mineral Processing Equipment Market Size 2022 | USD 20.6 Billion |

| Mineral Processing Equipment Market Forecast 2032 | USD 33.6 Billion |

| Mineral Processing Equipment Market CAGR During 2023 - 2032 | 5.1% |

| Mineral Processing Equipment Market Analysis Period | 2020 - 2032 |

| Mineral Processing Equipment Market Base Year |

2022 |

| Mineral Processing Equipment Market Forecast Data | 2023 - 2032 |

| Segments Covered | By Equipment Type, By Application, By End-user Industry, And By Geography |

| Regional Scope | North America, Europe, Asia Pacific, Latin America, and Middle East & Africa |

| Key Companies Profiled | Astec Industries, Inc., Multotec Pty Ltd., Caterpillar Inc., Komatsu Ltd., Eagle Crusher, McLanahan Corporation, FLSmidth A/S, Kleemann GmbH, Kemper Equipment, Metso Corporation, FEECO International, Inc., Sandvik AB, and Derrick Corporation. |

| Report Coverage |

Market Trends, Drivers, Restraints, Competitive Analysis, Player Profiling, Covid-19 Analysis, Regulation Analysis |

Mineral processing equipment encompasses a wide range of machinery designed to facilitate the extraction and processing of valuable minerals from ore deposits. This equipment is crucial in transforming raw ores into refined and marketable products. Common types of mineral processing equipment include crushers, grinding mills, classifiers, magnetic separators, flotation machines, and dewatering equipment. These tools are employed in various stages of the mineral processing workflow, such as crushing and grinding for size reduction, gravity separation for concentration, and flotation for separating minerals based on their surface properties. The applications of mineral processing equipment are diverse and span across multiple industries. In mining, these tools are used to extract metals and minerals from the Earth, ensuring efficient resource utilization. Additionally, mineral processing equipment finds applications in industries such as construction, ceramics, and pharmaceuticals, where refined minerals serve as essential raw materials.

The mineral processing equipment market has exhibited significant growth in recent years, propelled by the increasing demand for minerals across various industries globally. The surge in infrastructure development, coupled with the rising need for metals in manufacturing and energy sectors, has intensified exploration and mining activities. This heightened mining activity has, in turn, driven the demand for advanced mineral processing equipment to extract, refine, and separate valuable minerals from ores efficiently. Technological advancements have played a pivotal role in shaping the market landscape, with continuous innovations in automation, digitalization, and smart technologies. These advancements have enhanced the efficiency and sustainability of mineral processing operations, addressing challenges such as environmental impact and safety concerns.

Mineral Processing Equipment Market Segmentation

The global Mineral Processing Equipment Market segmentation is based on equipment type, application, end-user industry, and geography.

Mineral Processing Equipment Market By Equipment Type

According to the mineral processing equipment industry analysis, the crushers segment accounted for the largest market share in 2022. Crushers are essential equipment in the initial stages of mineral processing, where large raw materials are reduced in size to facilitate further processing. The growth of the crushers segment is closely tied to the expansion of mining activities, construction projects, and the manufacturing sector. One key driver of the crushers segment is the rising demand for construction aggregates in infrastructure development projects. The construction industry relies heavily on crushed materials for the production of concrete and asphalt, driving the need for efficient and high-capacity crushers. Additionally, the growing emphasis on sustainable and eco-friendly practices has led to the development of advanced crushers that offer better energy efficiency and reduced environmental impact. This has further fueled the adoption of crushers in the mineral processing industry.

Mineral Processing Equipment Market By Application

In terms of applications, the metal ore processing segment is expected to witness significant growth in the coming years. Metal ore processing involves the extraction and refinement of valuable metals from their ores, and efficient equipment plays a critical role in this complex process. As the global demand for metals continues to rise, driven by urbanization and industrialization trends, the metal ore processing segment experiences heightened activity. One significant driver of growth in this segment is the exploration and extraction of base metals, precious metals, and other minerals. Mining companies are increasingly investing in advanced mineral processing equipment to optimize extraction processes, improve recovery rates, and enhance overall operational efficiency. Moreover, technological advancements, including the integration of automation and digitalization, have contributed to the growth of the metal ore processing segment.

Mineral Processing Equipment Market By End-user Industry

According to the mineral processing equipment market forecast, the mining segment is expected to witness significant growth in the coming years. Mining operations are expanding to meet the needs of industries such as construction, energy, and manufacturing, and this surge in activity has driven the demand for advanced equipment to optimize the extraction and processing of minerals. The mining segment covers a broad spectrum of activities, including exploration, drilling, blasting, hauling, and processing, all of which require specialized machinery for increased efficiency and productivity. One of the primary growth drivers in the mining segment is the adoption of cutting-edge technologies, such as automation, artificial intelligence, and advanced sensor systems. These technologies enhance the precision and safety of mining operations while improving overall productivity.

Mineral Processing Equipment Market Regional Outlook

North America

Europe

Asia-Pacific

Latin America

The Middle East & Africa

Mineral Processing Equipment Market Regional Analysis

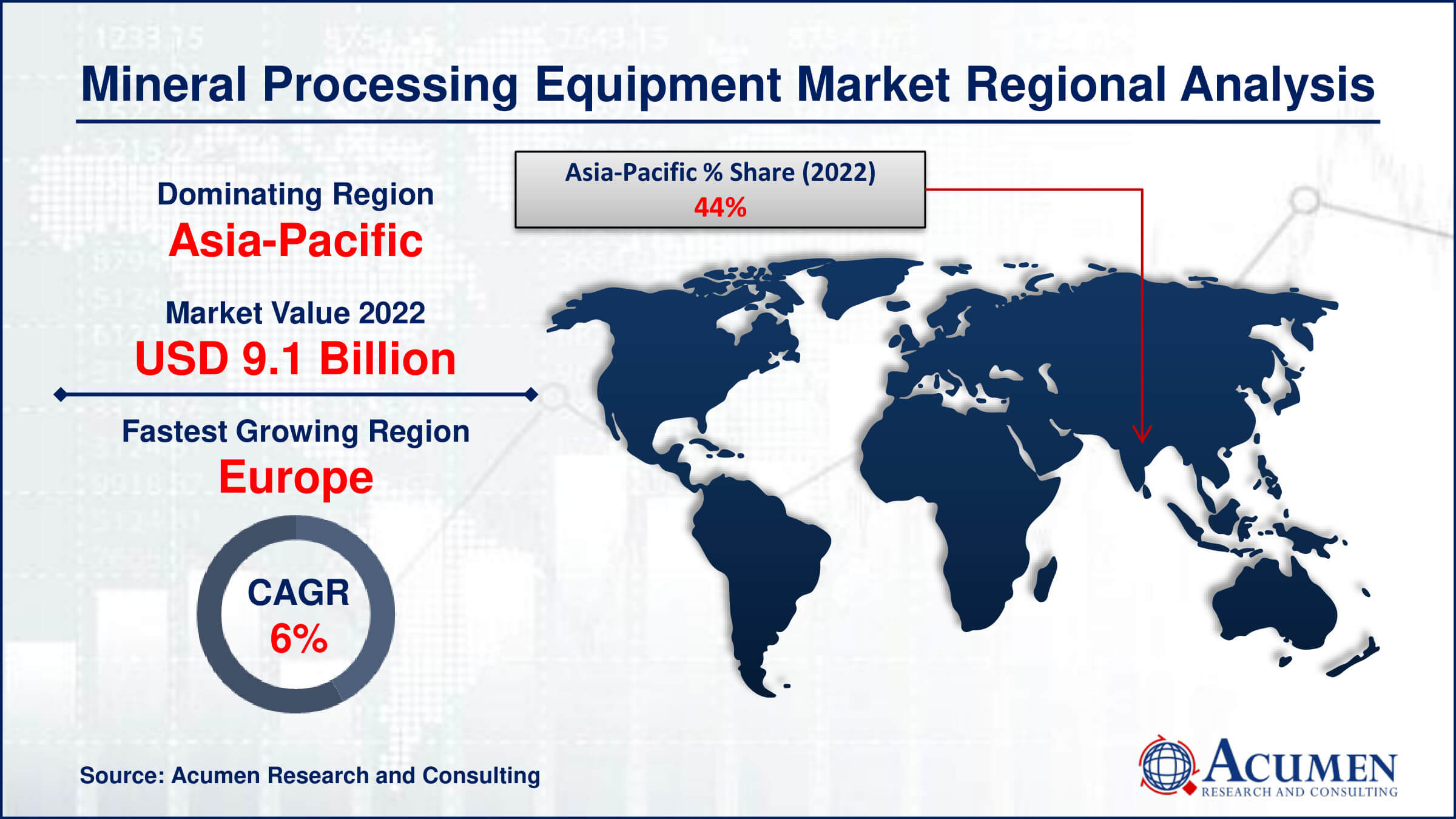

The Asia-Pacific region has emerged as a dominating force in the mineral processing equipment market, driven by the robust industrialization, urbanization, and infrastructure development witnessed across countries in this region. The demand for minerals and metals has surged significantly due to the rapid growth in the construction, manufacturing, and energy sectors, leading to increased mining activities. As a result, the Asia-Pacific region has become a key player in the global mineral processing equipment market, with a high concentration of mining projects and a growing need for advanced machinery to extract, process, and refine raw materials efficiently. China, in particular, stands out as a major contributor to the dominance of the Asia-Pacific region in the mineral processing equipment market. As the world's largest consumer of metals and minerals, China's industrial expansion has fueled a substantial demand for mineral processing equipment. Additionally, other countries in the Asia-Pacific, such as India, Australia, and Indonesia, are also significant players in the mining and mineral processing sectors, further bolstering the region's dominance. The presence of abundant natural resources, coupled with ongoing investments in technological advancements, positions the Asia-Pacific region at the forefront of the global mineral processing equipment market, and this trend is likely to continue as the demand for minerals remains robust in the foreseeable future.

Mineral Processing Equipment Market Player

Some of the top mineral processing equipment market companies offered in the professional report include Astec Industries, Inc., Multotec Pty Ltd., Caterpillar Inc., Komatsu Ltd., Eagle Crusher, McLanahan Corporation, FLSmidth A/S, Kleemann GmbH, Kemper Equipment, Metso Corporation, FEECO International, Inc., Sandvik AB, and Derrick Corporation.

Looking for discounts, bulk pricing, or custom solutions? Contact us today at sales@acumenresearchandconsulting.com

May 2018

January 2024

April 2025

September 2023